Laser cutting technology has revolutionized manufacturing and crafting. This method uses a high-powered laser beam to cut materials with precision and speed. Different materials respond uniquely to laser cutting, influencing the quality and efficiency of the process. Knowledge of suitable materials helps in achieving desired outcomes while minimizing risks.

In this blog post, we will explore various materials that can be laser cut using a fiber laser cutter and the specific advantages associated with each.Understanding what materials can be laser cut is crucial for optimizing results and ensuring safety.

What Materials Can Be Laser Cut

Laser cutting technology can handle a wide range of materials. These include wood, acrylic, paper, fabrics, metals, plastics, rubber, and glass. Each material offers unique benefits and applications. Choosing the right material ensures optimal results and safety. Laser cutting provides precision and versatility for various projects. Explore laser cutting to unlock creative and industrial possibilities.

What Materials Can Be Cut by a co2 Laser Cutter

While lasers excel at cutting metals, they can also process certain non-metallic materials, expanding their utility across different industries:

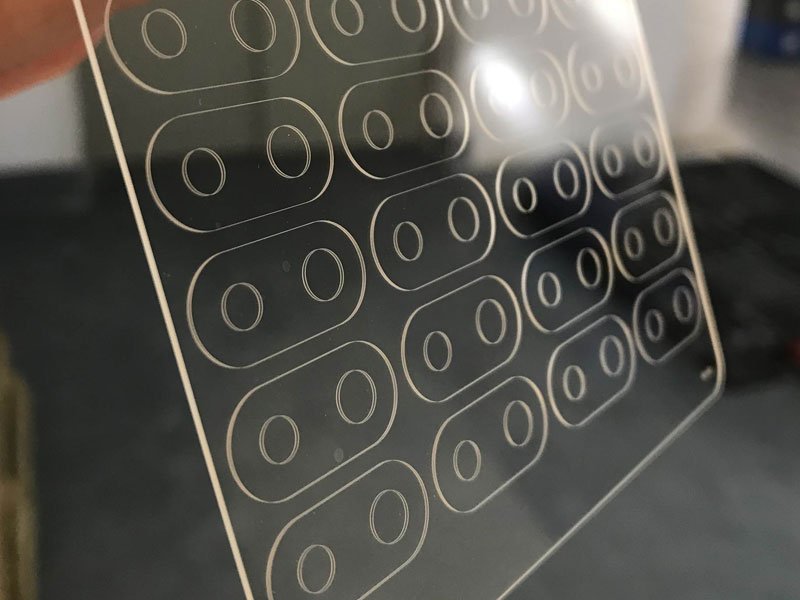

Plastics and Polymers: Different types of plastics, such as acrylic, polycarbonate, and ABS, can be laser cut. This method is often used for creating signs, displays, and components in the automotive and consumer goods industries.

Wood: Laser cutting can produce intricate designs and clean cuts in various types of wood, including plywood, MDF, and hardwoods. This is popular in the furniture, art, and model-making industries.

Paper and Cardboard: Laser cutting provides precision and speed for cutting and engraving paper and cardboard, making it ideal for packaging, invitations, and custom art.

Foam: Various foam materials used for packaging, insulation, and crafting can be laser cut with high precision.

Composites: CO2 laser cutters can handle composite materials, which are increasingly used in aerospace and automotive applications for their strength-to-weight ratio.

What Materials Can Be Cut By Industrial Fiber Laser Cutters

Fiber laser cutting machines are revolutionizing the manufacturing industry with their precision, speed, and versatility. As a business operating in the B2B space, understanding the range of materials that can be effectively processed with a fiber laser cutter is crucial. This knowledge not only helps in expanding your product offerings but also in tailoring solutions to meet diverse customer needs.

1. Metals

Fiber laser cutters are particularly renowned for their ability to cut a wide range of metals with high precision and speed. Here’s a closer look at some common metals that can be laser cut:

- Steel (Carbon and Stainless): Both carbon steel and stainless steel are ideal candidates for fiber laser cutting. The process allows for clean, burr-free edges, making it suitable for intricate designs and components. Stainless steel, in particular, benefits from a smooth finish that often requires no further processing.

- Aluminium: Aluminum’s reflective properties can pose a challenge for some laser cutters, but fiber lasers handle it effectively. The high power and focus of a fiber laser cutter ensure precise cuts, making it suitable for aerospace, automotive, and consumer electronics applications.

- Copper and Brass: These metals are also highly reflective but can be cut efficiently with a fiber laser. The ability to cut copper and brass expands the range of applications to include electrical components and decorative elements.

2. Alloys

Various metal alloys can be laser cut, each benefiting from the precision and efficiency of fiber laser technology. Examples include:

- Titanium Alloys: Used extensively in the aerospace and medical industries, titanium alloys can be cut with high precision, ensuring components meet stringent specifications.

- Alliages de nickel: Known for their high resistance to heat and corrosion, nickel alloys are commonly used in harsh environments. Fiber lasers provide the precision needed for these challenging materials.

3.Reflective Materials

One of the significant advantages of fiber laser cutters is their ability to handle highly reflective materials. Traditional CO2 lasers often struggle with these due to reflection issues, but fiber lasers, with their higher absorption rates, can cut reflective metals like aluminum, copper, and brass efficiently.

Other Materials for Laser Cutting

Céramique: While more challenging, thin ceramic materials can sometimes be cut with fiber lasers. This is particularly useful in the electronics industry where precision is critical.

Textiles: Various fabrics, including synthetic and natural fibers, can be laser cut to produce patterns, garments, and industrial textiles.

Glass: Special types of fiber lasers can etch or cut certain types of glass, though this is less common and typically requires specialized settings and equipment.

Rubber: another material suitable for laser cutting. Two primary types include natural rubber and synthetic rubber. Natural rubber comes from latex extracted from rubber trees. Synthetic rubber, made from petroleum-based monomers, offers enhanced properties like heat resistance.

Conclusion

Fiber laser cutters are incredibly versatile tools that can handle a wide array of materials, making them indispensable in various industries. From metals like steel and aluminum to non-metallic materials such as plastics and composites, the precision and efficiency of fiber laser technology provide unparalleled advantages. As a B2B provider of fiber laser cutting machines, offering solutions that cater to these diverse material needs will position your business as a leader in the market.

By understanding and leveraging the capabilities of fiber laser cutters, you can meet and exceed your customers’ expectations, driving innovation and growth in your industry. Whether you are targeting the aerospace sector, automotive industry, or consumer goods market, the ability to process a broad range of materials will be a key differentiator for your business.