Fiber laser cutting tables are game-changers in the manufacturing world. If you’re thinking about investing in one, you probably have a lot of questions. Let’s dive into everything you need to know about industrial fiber laser cutting table, covering key features, benefits, considerations, and top brands.

This guide aims to help you make an informed decision, all while keeping things simple and easy to understand.

What is a Industrial Fiber Laser Cutting Table?

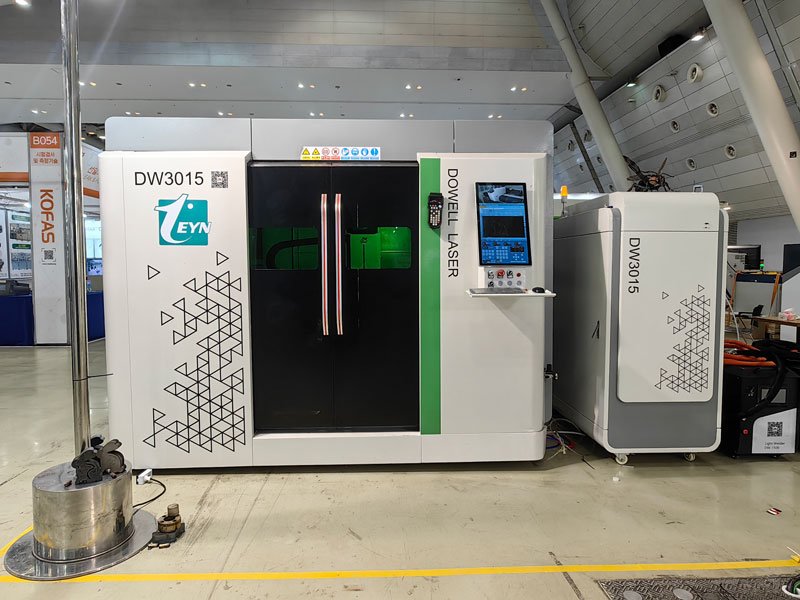

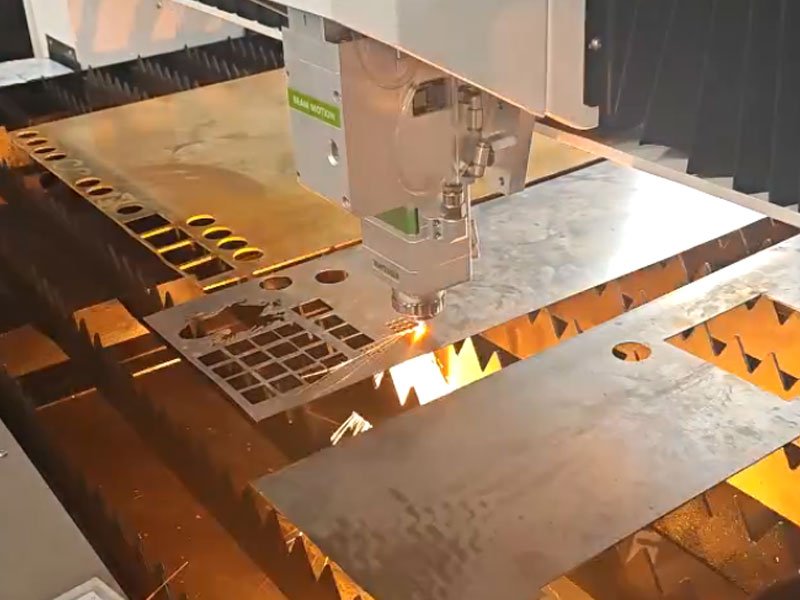

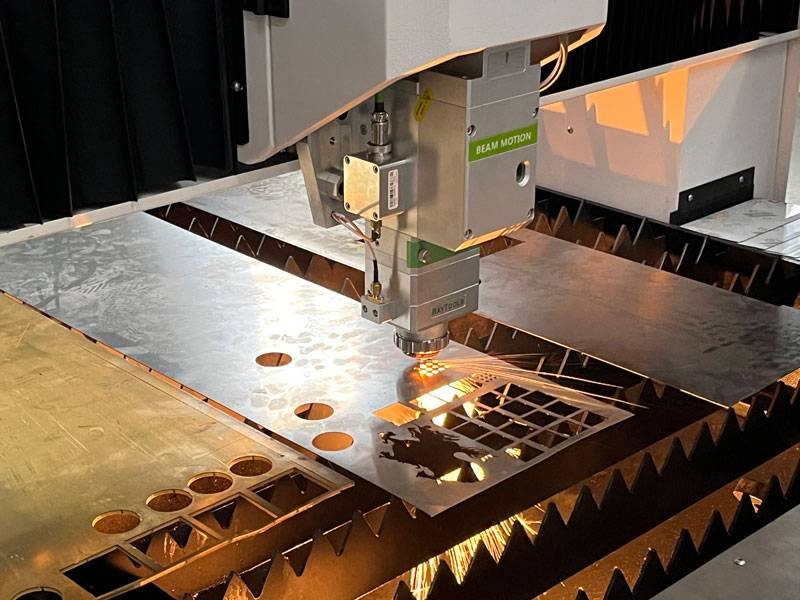

A fiber laser cutting table is a high tech machine used to cut and engrave materials, primarily metals. Unlike traditional cutting tools, these tables use a fiber laser beam, which is known for its precision and speed. The “table” refers to the flat surface where materials are placed for cutting.

Type of Fiber Laser Cutting Table

1. Flatbed Fiber Laser Cutting Tables

Description: Flatbed fiber laser cutting tables are the most common type. They feature a flat, horizontal bed où materials are placed for cutting. These machines are ideal for cutting large, flat sheets of material.

Caractéristiques:

- Large working area, typically ranging from 4’x4’ to 6’x12’.

- High precision and speed.

- Capable of cutting various materials including steel, aluminum, brass, and copper.

Ideal For:

- Metal fabrication

- Sheet metal processing

- Signage

- Automotive parts

2. Compact Fiber Laser Cutting Tables

Description: Compact fiber laser cutting tables are smaller and more affordable than their flatbed counterparts. They are designed for smaller projects and can fit in limited spaces.

Caractéristiques:

- Smaller working area, usually under 4’x4’.

- Lower power compared to larger models, suitable for thinner materials.

- Often designed for ease of use and portability.

Ideal For:

- Small businesses

- Hobbyists

- Prototyping

- Custom engraving

3. Combination Fiber Tube and Pipe Fiber Laser Cutting Tables

Description: These tables are specifically designed for cutting tubes and pipes. They feature specialized fixtures and rotary axes to handle round, square, and rectangular tubes.

Caractéristiques:

- Capable of cutting complex shapes and contours on tubes and pipes.

- High precision and speed.

- Often equipped with automatic loading and unloading systems.

Ideal For:

- Automotive and aerospace industries

- Structural engineering

- Furniture manufacturing

- Custom tubing and piping projects

4. Dual Fiber Laser Cutting Table

Description: Dual fiber laser cutting tables are specifically designed to handle both flat sheets and tubular materials. These advanced machines feature specialized fixtures and rotary axes, allowing them to cut round, square, and rectangular tubes with high precision and speed. This dual functionality makes them highly versatile and efficient for manufacturers with varied cutting needs.

Caractéristiques:

- Dual Cutting Capabilities: Capable of cutting both flat sheets and tubes/pipes, making them versatile for different types of projects.

- Specialized Fixtures and Rotary Axes: Designed to securely hold and rotate tubes, enabling precise cuts on round, square, and rectangular shapes.

- High Precision and Speed: Utilizes advanced fiber laser technology to achieve accurate and clean cuts at high speeds.

- Automatic Loading and Unloading Systems: Often equipped with automation features that streamline the cutting process and reduce manual labor.

- Advanced Software Integration: Comes with software that supports complex cutting patterns and efficient material usage through nesting capabilities.

Ideal For:

- Manufacturers with Diverse Production Needs

- Automotive and Aerospace Industries

- Structural Engineering and Construction

- Fabrication de meubles

- Metal Fabrication Shops

5. High-Power Fiber Laser Cutting Tables

Description: High-power fiber laser cutting tables are designed for heavy-duty applications. They come with higher wattage lasers, capable of cutting thicker materials at faster speeds.

Caractéristiques:

- Laser power typically ranges from 6kW to 15kW or higher.

- Capable of cutting thick metals with high precision.

- Often integrated with advanced cooling systems to handle the increased power.

Ideal For:

- Heavy industrial applications

- Thick metal cutting

- High-volume production environments

- Industries requiring rapid processing of robust materials

6. Portable Fiber Laser Cutting Tables

Description: Portable fiber laser cutting tables are designed for mobility. They are smaller and lighter, allowing for easy transportation and setup.

Caractéristiques:

- Compact and lightweight design.

- Typically lower power, suitable for thinner materials and small-scale projects.

- Easy to transport and set up in different locations.

Ideal For:

- On-site repair and fabrication

- Small workshops

- Educational institutions

- Mobile businesses

What Sets Fiber Laser Cutting Apart?

Fiber laser cutting offers several distinct advantages over traditional cutting methods, such as:

- Unparalleled Precision: Fiber lasers can deliver remarkably accurate cuts, with tolerances as tight as ±0.1 mm, making them ideal for intricate designs and complex parts.

- Exceptional Speed: Fiber laser cutting is significantly faster than other cutting techniques, with cutting speeds up to 10 times faster than CO2 lasers or plasma cutters.

- Polyvalence: Fiber lasers can handle a wide range of materials, from thin sheet metal to thick plates, and can even cut through reflective materials like aluminum and stainless steel.

- Efficacité énergétique: Fiber laser cutting systems are more energy-efficient than their CO2 counterparts, reducing operational costs and environmental impact.

- Low Maintenance: Fiber lasers require less maintenance compared to other laser technologies, with fewer consumable parts and longer service intervals.

Why Choose a Fiber Laser Cutting Table?

1. Precision and Quality

Fiber lasers offer unmatched precision. They can cut complex shapes and intricate designs with clean edges, reducing the need for additional finishing. This means higher quality products right off the table.

2. Speed and Efficiency

Fiber lasers cut faster than traditional methods. This increased speed leads to higher productivity, allowing you to complete more projects in less time.

3. Versatility

These machines can cut a variety of materials, including steel, aluminum, brass, and copper. Some models can even handle non-metal materials like plastics and composites.

4. Lower Operating Costs

Fiber lasers are more energy-efficient compared to CO2 lasers. They also have fewer moving parts, which means less maintenance and lower costs over time.

Factors to Consider When Choosing a Fiber Laser Cutting Table

Quand shopping for a fiber laser cutting table, consider these essential features:

1. Laser Power

Measured in watts, laser power determines quoi materials and thicknesses you can cut. For most small to medium businesses, a 1kW to 3kW laser is sufficient. Higher power lasers (up to 10kW) are available for cutting thicker materials quickly.

2. Zone de coupe

The size of the cutting area matters based on the size of materials you typically work with. Common sizes range from 4’x4’ to 6’x12’. Choose a size that fits your typical project needs.

3. Software Compatibility

Good software can make a big difference in ease of use and efficiency. Look for tables compatible with popular CAD/CAM software like AutoCAD, SolidWorks, and CorelDRAW. User-friendly software with nesting features can optimize material usage, saving you money.

4. Build Quality

A sturdy frame and high-quality components ensure durability and precision. Check for features like automatic lubrication systems and protective covers to keep the machine in top condition.

5. Automation Features

Advanced models come with automation features like automatic loading and unloading, which can further boost productivity and reduce labor costs.

Considerations Before Buying

1. Budget

Fiber laser cutting tables are a significant investment. Prices can range from $20,000 for small, basic models to over $500,000 for high-end industrial machines. Consider your budget and look for financing options if needed.

2. Space Requirements

Ensure you have enough space to accommodate the machine and its operation. Consider the footprint of the machine and the space needed for loading and unloading materials.

3. Support and Training

Choose a manufacturer that offers good customer support and training. Proper training is crucial for maximizing the efficiency and lifespan of your machine.

4. Maintenance

Regular maintenance is key to keeping your machine running smoothly. Understand the maintenance requirements and costs associated with the model you choose.

Top Fiber Laser Cutting Table Brands

Here are some of the leading brands in the industry:

1. Trumpf

Known for their high-quality and reliable machines, Trumpf offers a range of fiber laser cutting tables suitable for various industrial applications. Their machines are known for precision, speed, and durability.

2. Bystronique

Bystronic is a global leader in sheet metal processing. They provide advanced fiber laser cutting technology with a focus on automation and ease of use.

3. Amada

Amada offers a variety of fiber laser cutting tables designed for both small businesses and large-scale industrial operations. They are known for their robust build and advanced features.

4. Mazak

Mazak’s laser cutting tables are renowned for their innovative technology and reliability. They offer solutions for both heavy-duty industrial applications and smaller operations.

5. Han’s Laser

A leading Chinese manufacturer, Han’s Laser offers a range of cost-effective and high-performance fiber laser cutting tables. They are a good choice for those looking for a balance of affordability and functionality.

Conclusion

Fiber laser cutting tables offer significant advantages in precision, speed, and versatility. Quand choosing a machine, consider factors like laser power, cutting area, software compatibility, build quality, and automation features. Keep your budget, space requirements, and the availability of support and training in mind.

Investing in a fiber laser cutting table can greatly enhance your production capabilities and product quality. Whether you are a small business or a large manufacturer, the right machine can open up new possibilities and drive your business forward.

Choosing the right fiber laser cutting table requires careful consideration, but with the right information, you can make a choice that will benefit your business for years to come.