wholesale customized round tube laser cutting machine for Sale

- Marque: MACHINE LASER DOWELL

- Type de laser : laser à fibre.

- Puissance: 1000w 1500w 2000w 3000w 6000w

- Cooling Mode: WATER COOLING

- Applicable Material Metal

Introduction

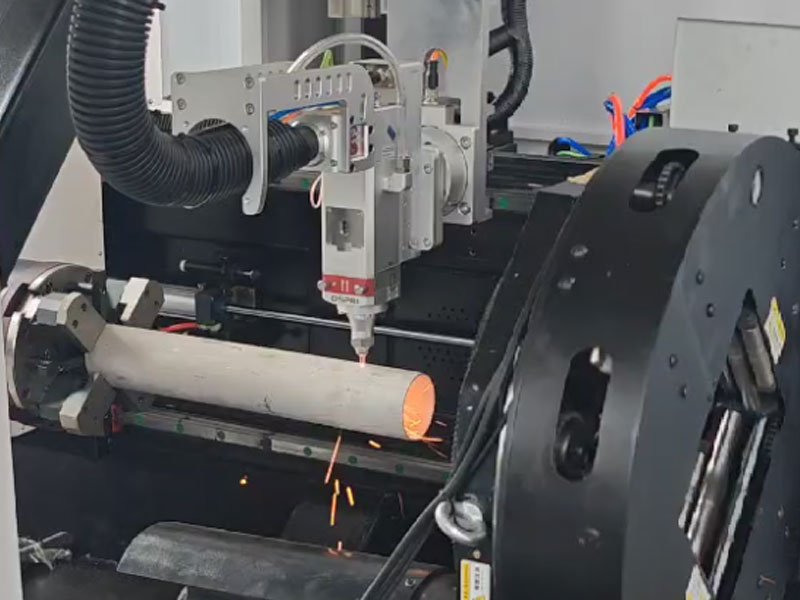

Circular tube laser cutting machines / round tube laser cutting machines are specialized tools designed to cut round tubes with high precision and efficiency. They utilize advanced laser technology to create intricate shapes and designs in various materials, making them essential in industries such as automotive, aerospace, and manufacturing.

Circular tube laser cutting machines are advanced manufacturing tools that provide high-speed, precise cutting capabilities for round tubes, making them indispensable in modern production environments.

Paramètres techniques

- Marque : DowellLaser

- Laser Source Brand:MAX / RECI/IPG/RAYCUS

- Power: 1000w-12kw

- Products handled:Tube

- Graphic Format Supported: AI, PLT, DXF

- Voltage:380V

- CNC or Not:Yes

- Applicable Industries:Metal Cutting Industry

- Core Components:Motor, Laser generator

- Cutting speed:Max 0.8s/cut(Depending on material thickness)

- Machine repeat positioning accuracy:±0.05mm/1000mm

- Place of Origin:Shandong, China

best circular tube laser cutting machine for sale

Video

laser cutting Round & square tube

circular tube laser cutting machine video

Caractéristiques

Polyvalence: Tube laser cutting machines can process a wide range of shapes, including round, square, and rectangular tubes. This flexibility allows manufacturers to create complex designs and components efficiently.

Precision and Speed: The use of fiber lasers enables these machines to cut through thick-walled tubing with high accuracy. The CNC control systems guide the laser beam, ensuring consistent and reliable cuts, which is crucial for high production environments.

Automatisation: Many tube laser cutting systems include automated features such as bundle feeders. These systems enhance accuracy and safety by minimizing manual handling, thus reducing the risk of errors during the cutting process.

Applications: Tube laser cutting machines are widely used in various sectors, including mechanical engineering, furniture manufacturing, and system construction. They allow for innovative design possibilities, increasing demand for laser-cut tubes and profiles.

Construction: The machines typically feature a stable frame to support the tubes during cutting, with a laser head mounted on a gantry that moves along the tube’s length. This design contributes to the machine’s efficiency and effectiveness in cutting operations.

customized 200MM round tube fiber laser cutting machine

DOWELL round tube laser cutting machine factories has 15 years of experience in laser equipment manufacturing. The round tube laser equipment produced is exported to Egypt, Russia, Saudi Arabia, Egypt and other countries. It can meet the customized needs of customers. 200mm 350mm can be customized, and we provide you with the most competitive price on the market.

If you have customized needs or your tube is a special model, you can understand to consult us and get the latest circular tube laser cutting machine price.

FAQ

How much is circular tube laser cutting machine price

The price of a round tube laser cutting machine varies depending on specifications such as power, size, and features. Generally, each machine costs about $2,500 to $80,000.

When considering a purchase, it is important to evaluate the specific needs of your operation and compare different models and features to find the machine that best fits your budget and requirements.

Best circular tube laser cutting machine brand

Accurl: Accurl machines are known for their Accuracy series, which are efficient, versatile, and capable of cutting a wide range of materials with precision. They emphasize a balance between speed and accuracy, making them suitable for industries that require high-quality results.

Dowell laser: This brand specializes in CNC laser tube cutting machines, offering customizable solutions with power options ranging from 1000W to 6000W. Dowell is known for its state-of-the-art technology and has a reputation in the industry for providing high-precision cutting.

HGSTAR: Their SMART TUBE6015 model is known for its ability to cut a variety of tube shapes, including round tubes, with fast speeds and minimal waste. They focus on advanced features that increase cutting efficiency and accuracy.

Style CNC: They offer a range of fiber laser tube cutting machines with various power options, known for their affordability and effectiveness in cutting metal tubes.

Laser à bisons: This brand is known for its advanced laser cutting technology, offering machines capable of handling different tube shapes and sizes, emphasizing high speeds and high-quality cutting.

What is the cutting accuracy of the round tube laser cutting machine?

With advanced laser cutting technology and high-precision cutting heads, clean and precise cutting can be achieved with less post-processing workload.

What is the cutting thickness range of the circular pipe laser cutter?

The cutting thickness is generally between 0.5mm and 25mm, depending on the laser power and the type of material being cut.

What is the cutting diameter range of the round tube laser cutting equipment?

The cutting diameter ranges from 10mm to 460mm, which can meet the cutting needs of round tubes of various sizes.

What are the main types of round tube fiber laser cutting machine?

Mainly including: ordinary type, large closed type, automatic loading and unloading, plate and tube integration, multi-chuck and other types

How to choose a circular tube laser cutting machine that suits you

Matériaux de coupe et épaisseur

Choose the appropriate laser power according to the type of material (such as stainless steel, aluminum, carbon steel, etc.) and thickness to be cut. Equipment with different powers is suitable for different material thicknesses.

Puissance laser

Laser power directly affects cutting speed and cutting thickness. Generally speaking, the higher the power, the stronger the cutting ability and the thicker the material.

Cutting accuracy

Make sure that the selected equipment can meet the required cutting accuracy. High-precision laser cutting machines can reduce post-processing work and improve production efficiency.

Automation degree

Consider the degree of automation of the machine, such as whether it is equipped with an automatic loading and unloading system. This can improve production efficiency and reduce manual operation.

Operation interface

Choosing equipment with a friendly operation interface can simplify the operation process, reduce learning time, and improve work efficiency.

Equipment size and floor space

According to the space in the production workshop, choose a laser cutting machine of the right size to ensure that the equipment can be installed and operated smoothly.

After-sales service and technical support

Choose a brand that provides good after-sales service and technical support so that you can get help in time when there is a problem with the equipment.

Budget

Choose the right equipment according to the budget to ensure the best balance between performance and price.

Brand reputation

Choosing a laser cutting machine from a well-known brand usually provides better quality assurance and technical support.

User reviews and cases

Read other users’ reviews and use cases to understand the actual performance and reliability of the equipment and make a more informed choice