China 3D 5 Axis Laser Tube Cutting Machine for Sale

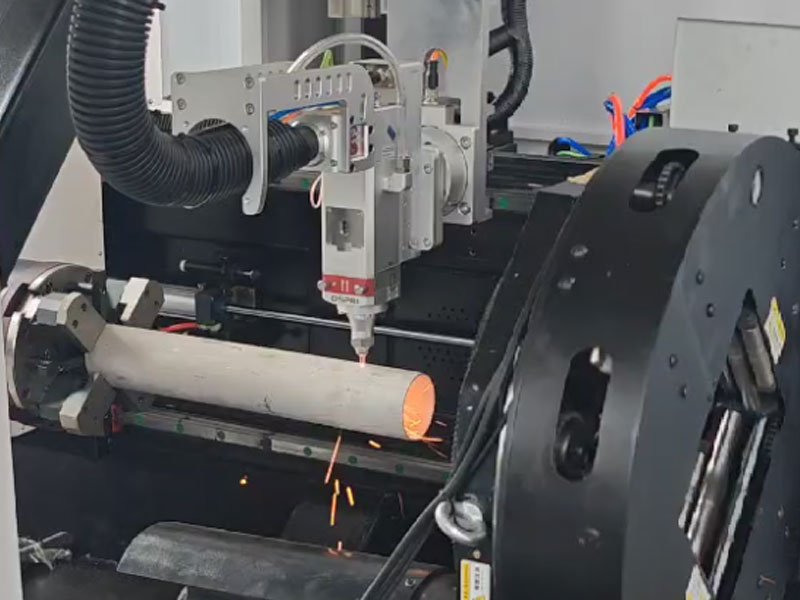

- The 5 Axis laser tube cutting machine can perform 360-degree full-range rotation

- Precise cutting, tilt cutting, bevel cutting and other complex processing at different angles.

- It can achieve rapid cutting of various special-shaped tubes such as round tubes, square tubes, oval tubes, U-shaped tubes, etc.

- It has low energy consumption and high efficiency, and can realize the one-time processing of 6-meter long tubes.

Introduction

5 Axis tube laser uses high-energy laser beams to quickly and accurately cut tubes, while using a five-axis linkage system to achieve precise processing of complex shapes and angles. This technology not only improves processing accuracy, but also greatly shortens production cycles.

A 5-axis laser tube cutting machine is a sophisticated piece of equipment designed to cut various shapes and sizes of tubes and pipes with high precision. The term “5-axis” refers to the machine’s ability to move and manipulate the laser cutting head along five different axes, allowing for complex cuts and angles.

What is the five axis?

Axis #1: Moves the material left to right (or right to left) horizontally.

Axis #2: Moves the laser head front to back (or back to front) across the material.

Axis #3: Moves the laser head up and down above the material.

Axis #4: Pivots the laser head on a radius on the same horizontal plane as Axis #1.

Axis #5: Rotates the laser head on a 360-degree radius above the laser nozzle

Vidéo de la machine de découpe laser à fibre à tube biseauté

Vidéo de la machine de découpe laser à fibre à tube biseauté

Benefits of 5 Axis Laser Pipe Cutting

- Precision and Efficiency: The ability to cut complex shapes and angles with high accuracy and minimal rework.

- Polyvalence: Suitable for a wide range of materials and applications, including thin-walled tubes and complex profiles.

- Productivity: Reduces the need for multiple machines and manual operations, streamlining the production process and reducing costs

Paramètres techniques

- Marque : DowellLaser

- Power: 3000w-60kw 5 axis pipe laser cutter

- Working width (mm):6m 9m 12m 24m

- Maximales Ladegewicht: 374 Pfund.

- Positioning accuracy: ±0.03mm/n

- Repeat positioning accuracy: 0.02mm

- Z-axis travel: 120mm

- Conceptions personnalisables

- Maximale Positionierungsbeschleunigung: 2,4 G

- Stromversorgung: dreiphasig 380 V/50/60 Hz

- Lieu de production : Chine

- Très grand format personnalisable

5 axis laser tube cutting machine installation process

5-axis tube laser Configuration

5 axis laser cutting head

Adapt to various laser interfaces, dual anti-collision system, built-in follow-up focus module, three protective mirrors sealed and dust-proof, automatic focus

5-axis pipe laser Cutting system

Equipped with BCW profile scanner, it can effectively detect and compensate for the deformation of steel sections, support various cutting scenarios, quickly draw and efficiently arrange samples, and promote the capacity upgrade of the steel structure industry.

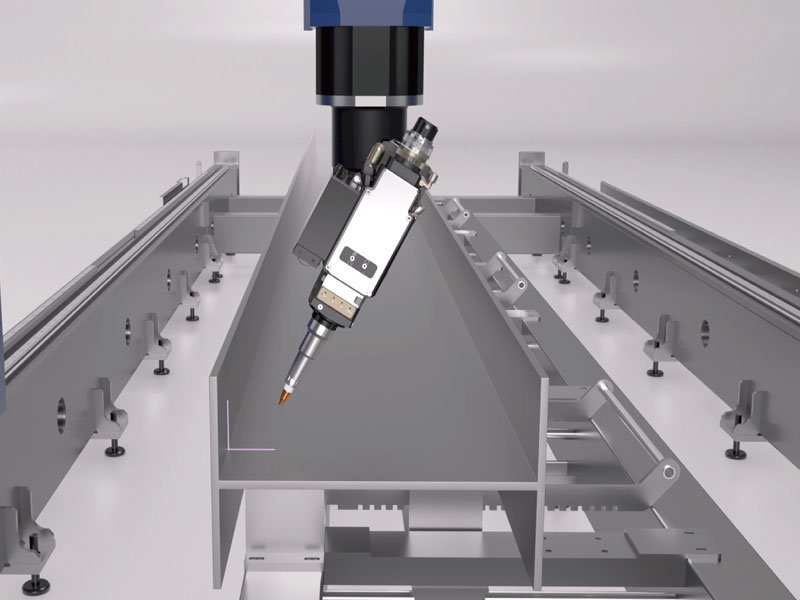

3D 5 axis swing axis

Suitable for 3D sheet metal processing, hot forming steel processing, A axis can rotate ±100°, C axis can rotate ±200°, harmonic integrated motor, high quality precision processing

5 axis laser tube cutting machine Features

Multi-axis Capability: Unlike traditional laser cutters that typically operate in 2 or 3 axes (X, Y, Z), a 5-axis laser tube cutter can move the laser head in five different axes. This allows it to cut complex shapes and patterns on tubes from various angles.

Polyvalence: The ability to move the laser head in multiple axes gives the machine versatility in cutting tubes of different diameters and lengths, and at various angles and contours. This makes it suitable for cutting complex geometries, such as mitred cuts, slots, holes, and chamfers.

Précision: 5-axis laser tube cutters offer high precision and accuracy, which is crucial for industries requiring intricate designs and tight tolerances.

Automation and Efficiency: These machines are often equipped with advanced software for programming and control, allowing for automated cutting processes. This improves efficiency and reduces production time.

Applications: They are used in various industries such as automotive, aerospace, construction, and furniture manufacturing, where tubes and pipes need precise cutting for components like frames, exhaust systems, structural elements, and more.

Complex Part Production: One of the main advantages is the ability to produce complex parts in a single setup, minimizing the need for secondary operations and reducing material waste.

application

3D 5 Axis laser tube cutting machine is widely used in the processing of various metal tubes, such as stainless steel, carbon steel, aluminum alloy, etc. It plays an important role in the automotive manufacturing, aerospace, petrochemical, architectural decoration and other industries. Especially in the field of high-precision and high-efficiency tube processing, the five-axis high-speed laser tube cutting machine has become an indispensable production tool.

How Much is A Bevel 5 axis laser cutting tube price

The three-dimensional five-axis bevel laser tube cutting machine price is generally around US$26134.80-71526.83. The higher the power, the higher the price. This is related to brand awareness, manufacturer’s strength, configuration, power size, etc.

These prices reflect a range of options from more affordable models to high-end industrial machines. The specific choice will depend on the required power, precision, and additional features needed for your application.

FAQ

What types of materials can be cut with a 5-axis laser tube cutting machine?

These machines can cut various metals including carbon steel, stainless steel, galvanized steel, aluminum, brass, and copper

What is the maximum cutting angle for bevel cuts?

Many 5-axis laser tube cutting machines can perform high-quality bevel cuts up to 45°

What is the typical tube diameter range for these machines?

The tube diameter range can vary by model, but it’s often between 20-350mm

How does a 5-axis laser cutter differ from a standard 3-axis machine?

A 5-axis machine can cut 3D shapes and complex geometries, while a standard 3-axis machine is limited to 2D cutting on flat sheets

What is the positioning accuracy of a 5 axis laser pipe cutting?

The positioning accuracy can be as precise as 0.02mm, depending on the specific model

Can 3D 5 axis laser pipe cutting machines handle different tube shapes?

Yes, 3D 5 axis laser pipe cutting machine can process round tubes, square tubes, rectangular tubes, oval tubes, channel steel, I-beams, and various other profiles