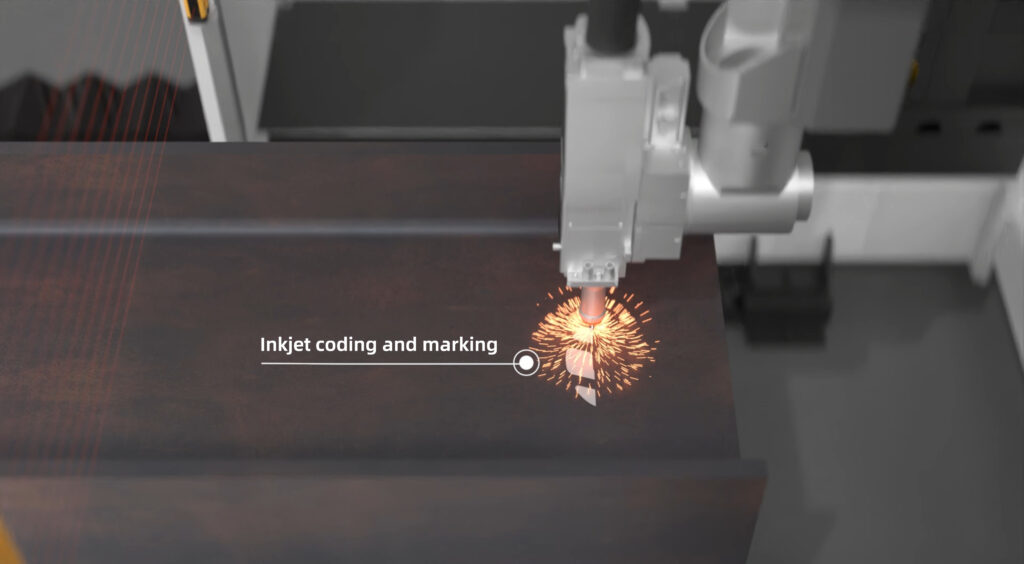

Integrates multi-process composite machining including laser cutting, drilling, and grooving.

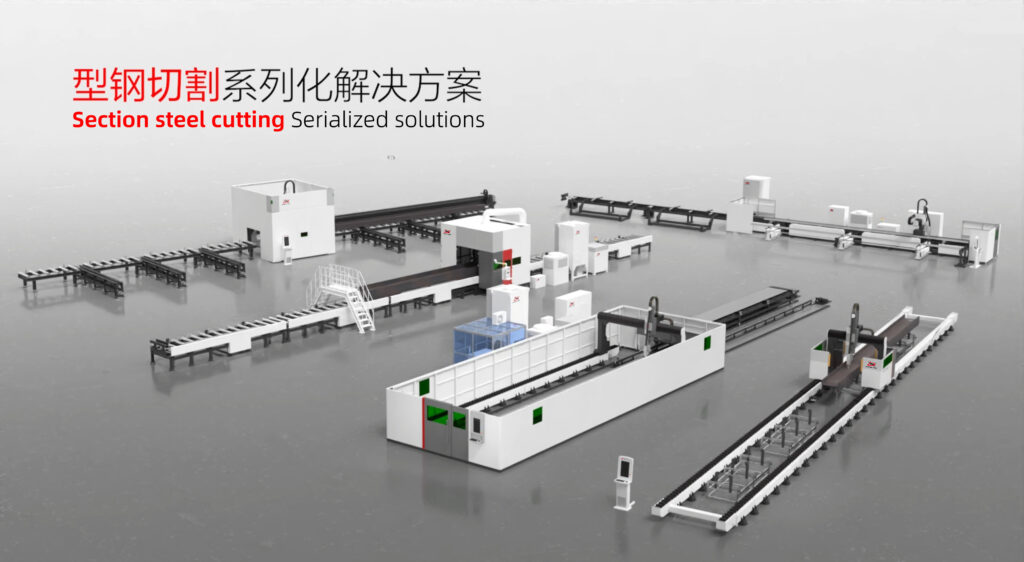

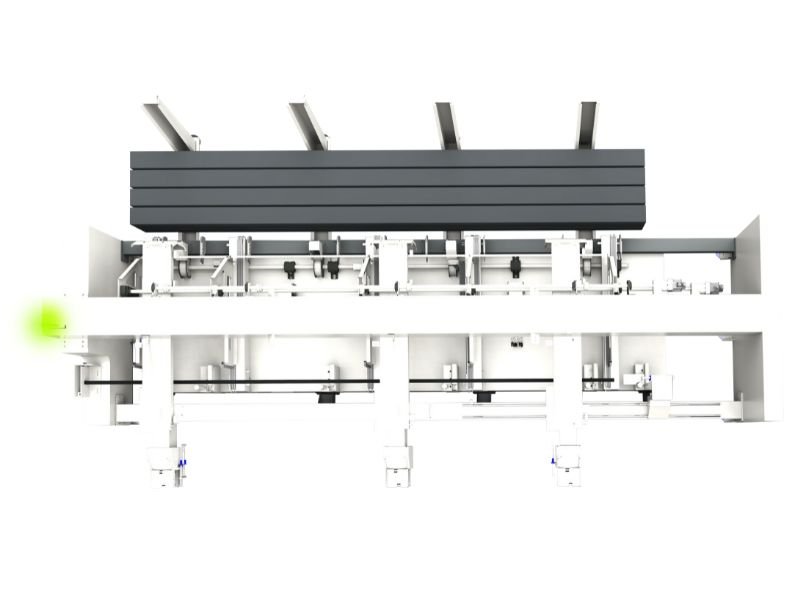

Gantry-type Section Steel Laser Composite Processing Center

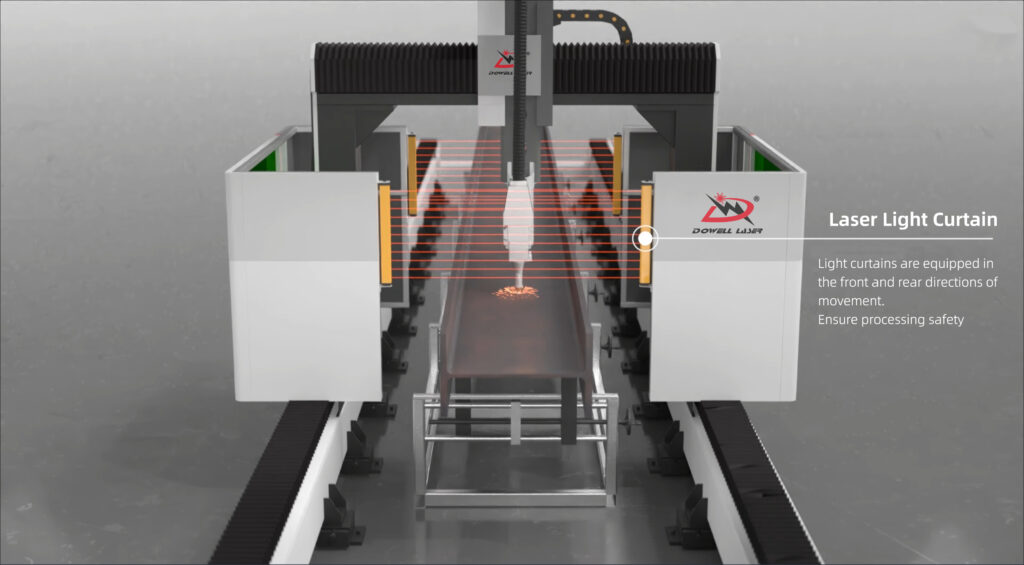

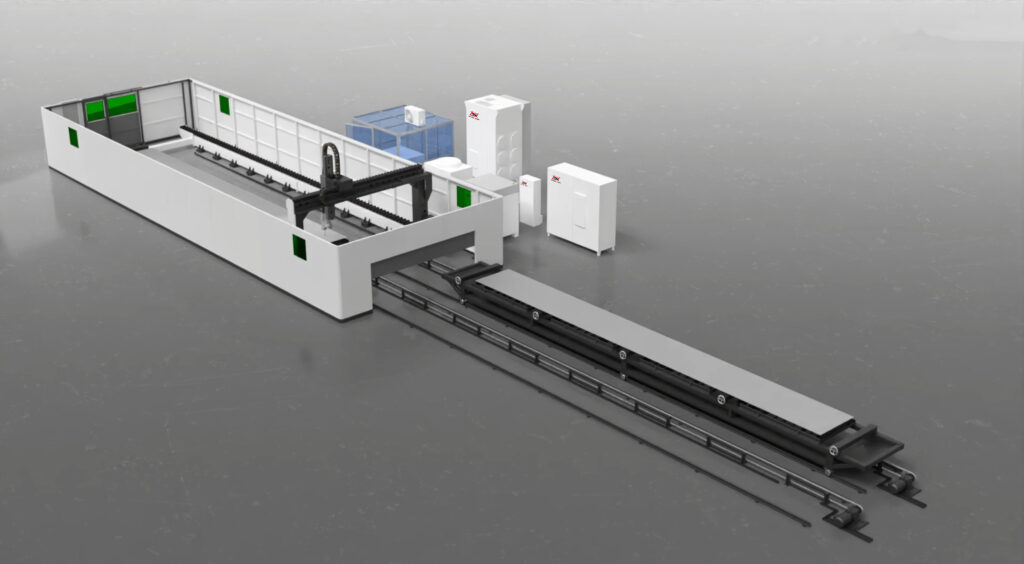

Equipped with a high-power laser system and a high-precision CNC system, it is suitable for processing various types of steel profiles such as H-beams, channel steel, and angle steel. The high-rigidity gantry frame ensures stable operation, and multiple processes are completed in a single clamping, significantly shortening the process cycle, reducing costs and increasing efficiency, empowering the automated upgrade of steel profile processing in the steel structure and construction machinery industries.

About Our Collection

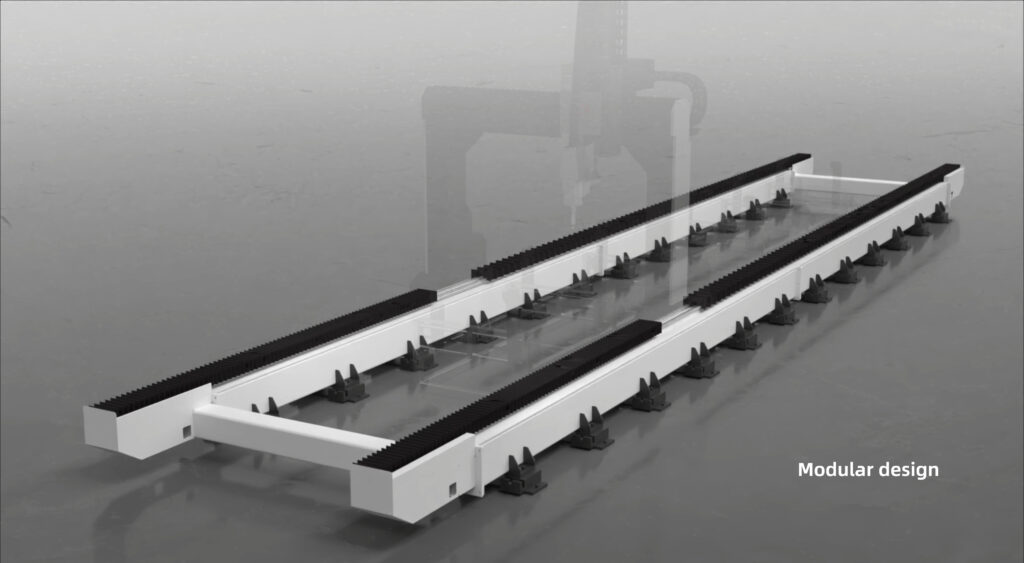

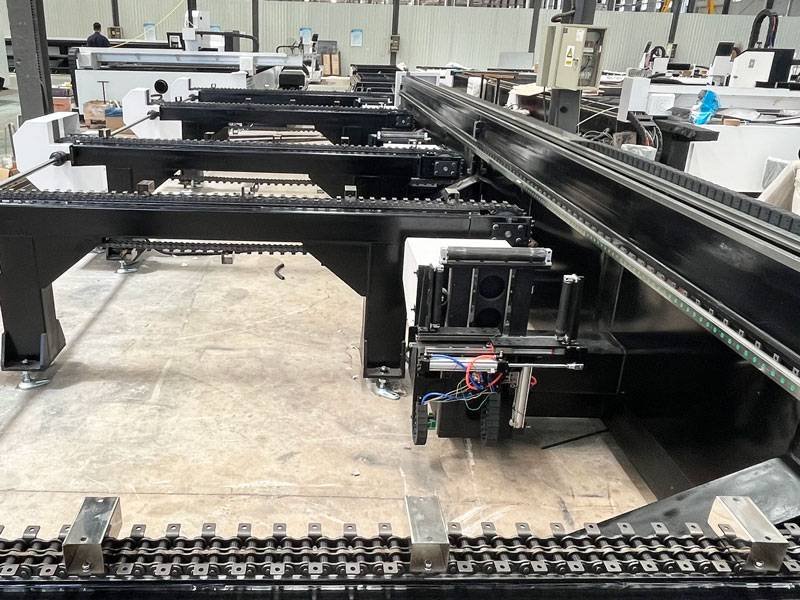

Automatic Loading Function + Modular Design

This device integrates an intelligent automatic loading and unloading system with multi-process composite machining capabilities. It features a high-power fiber laser and a high-precision CNC system, combined with a high-rigidity gantry frame and stable transmission components. The intelligent loading and unloading device automatically handles the entire process of loading, positioning, and unloading profiles, eliminating the need for manual intervention, significantly saving labor costs, and completely eliminating high-intensity handling operations. It also integrates multiple processes such as cutting, drilling, grooving, and chamfering, allowing for multi-process machining in a single clamping operation, saving process turnaround time and directly increasing processing efficiency by more than 50%!

Get To Know Us

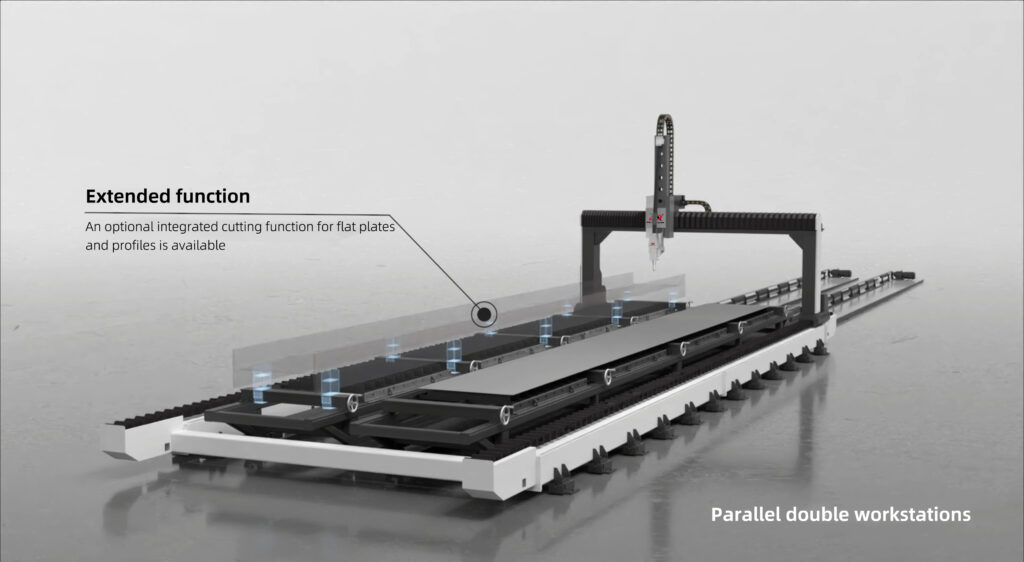

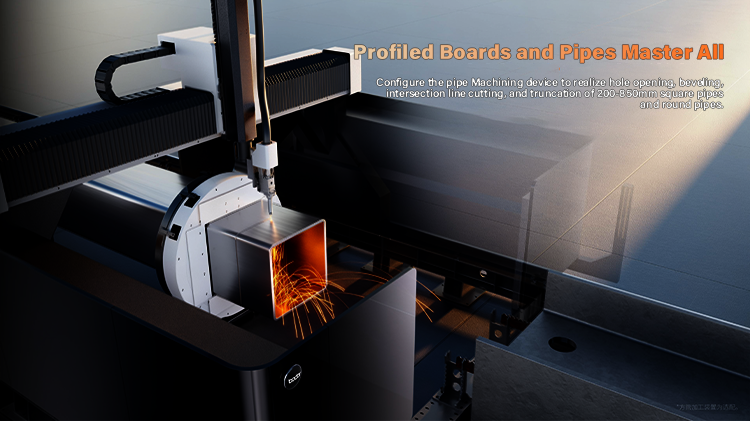

Multi-functional Laser Composite Processing Center

The Dowell Laser multi-functional composite laser processing center for steel sections, plates, and pipes. It is a versatile expert in the steel structure industry, capable of handling all types of materials including sections, plates, and pipes with ease.The equipment features a three-dimensional five-axis laser head, which can process both flat sheets (supporting bevel cutting on sheets) and I-beams, H-beams, channel sections, andangle steels. Additionally, it can meet the processing needs of square tubes, roundtubes,variable diameter beams, widened wing plates, crane beams, automotive longitudinalbeams,and spherical flat steel through non-standard configurations.

Benefits & Advantages

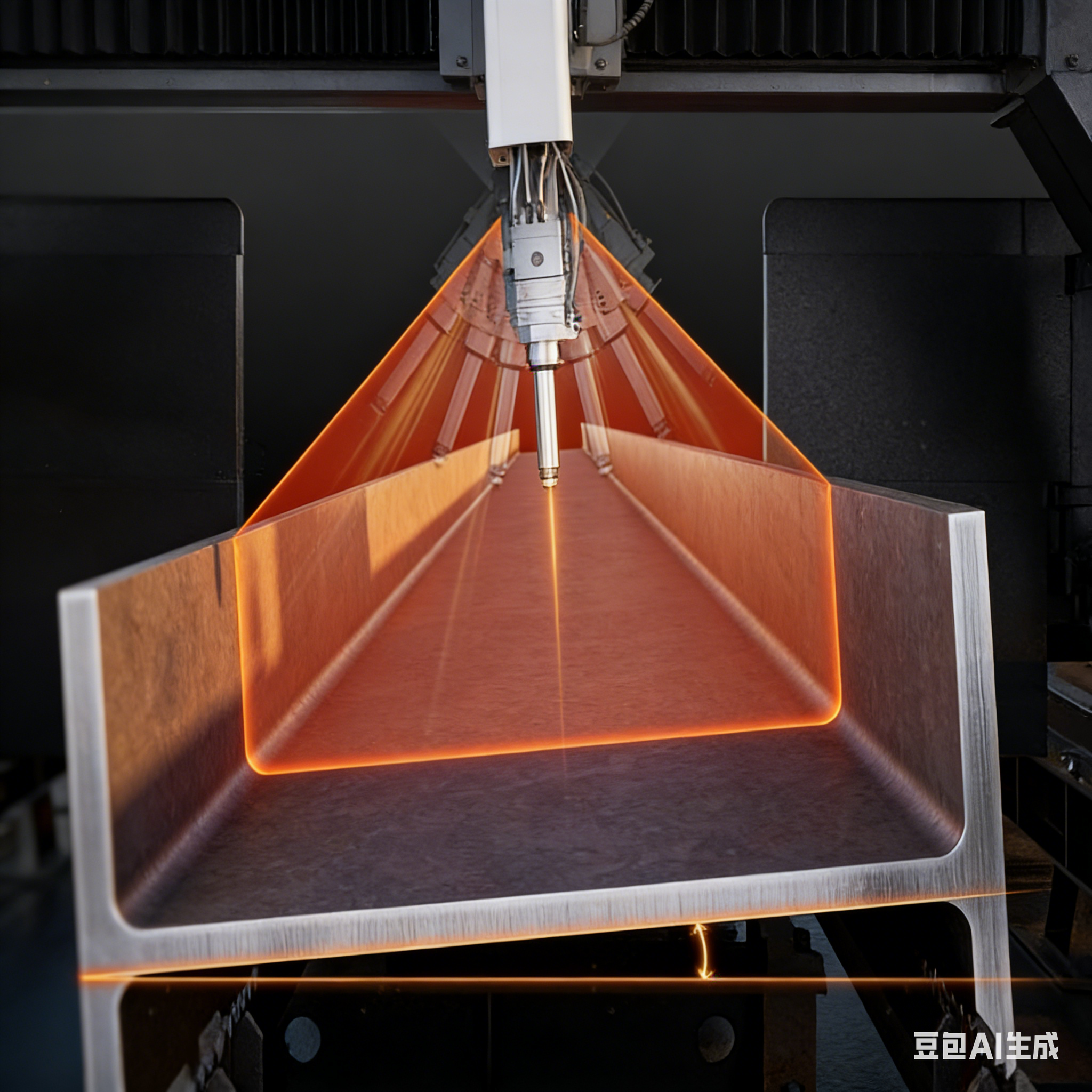

Dowell Laser H-beam Section Laser Cutting Processing Center | Powered by high-power fiber laser, specifically designed for cutting H-beams, I-beams, and other structural steel sections. It delivers burr-free, bevel-free, single-pass cutting. The high-rigidity machine body and precise CNC system ensure high cutting accuracy and stable operation. It is adaptable to various steel section specifications, providing powerful capabilities for efficient cutting operations in the steel structure industry.

Equipment Property

Locking Holes One-time Molding

Five-axis Linkage Cutting

Adapt the Tekla Drawings

Intelligent Correction and Positioning

Multi-functional Laser Cutting

Are you still struggling with the need for multiple machines and frequent line changes for cutting various types of sheet metal and profiles?

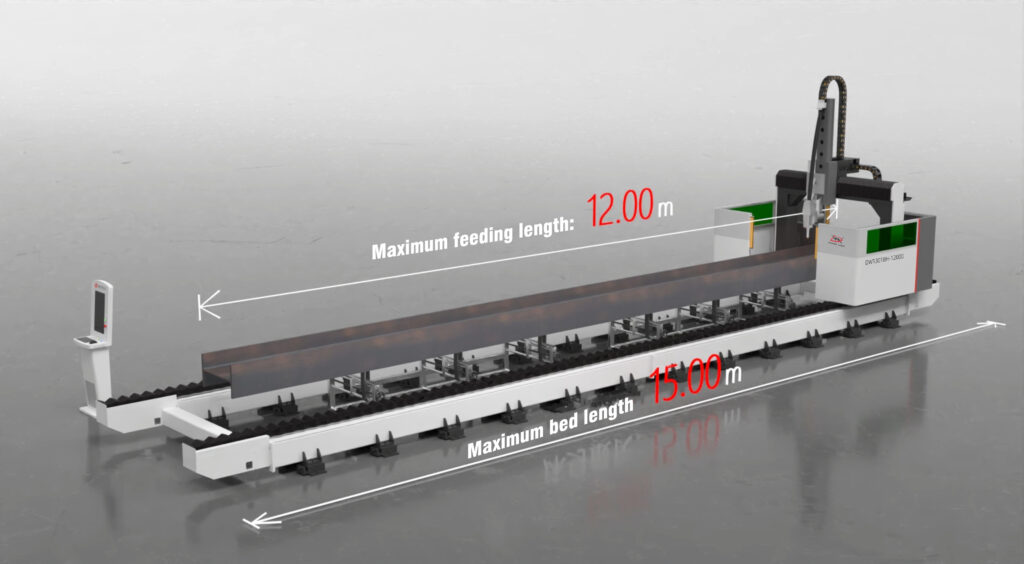

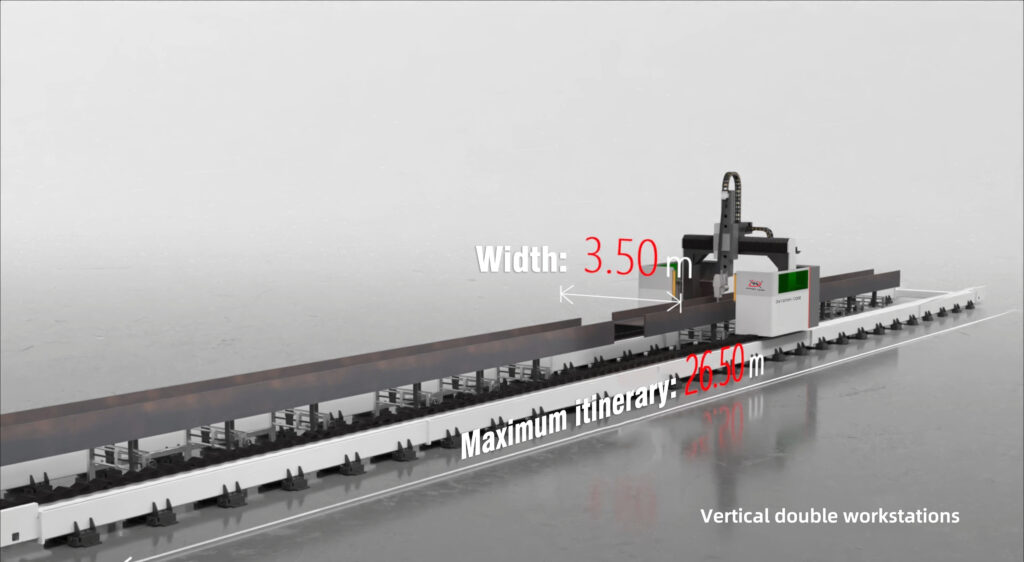

Dowell Laser’s automatic loading and unloading gantry-type section steel laser composite processing center breaks through processing limitations, offering a single machine compatible with cutting four major types of workpieces: H-beams, round pipes, square pipes, and flat plates. It provides an efficient and integrated processing solution for industries such as steel structures, construction machinery, and metal fabrication!

Parámetros técnicos

Technical Parameters of Gantry-type Section Steel Laser Composite Processing Center | Dowell Laser: A comprehensive overview of core parameters such as laser power, processing accuracy, and compatible profiles. Suitable for processing various types of steel sections, including H-beams and channel steel, providing clear reference for equipment procurement and production line planning.

Item.

Parameters.

Processing type

Plate, I-beam, H-beam, channel steel, anglesteel

The range of work

Profile: 100*100mm~1500*600mm(width*height) Plate straight cutting: 3200mm*28000mm(width*length) Plate groove: 2800mm*28000mm(width*length)

Equipment travel

Standard stroke 28000mm

Max. weight of pipe/plate

Maximum load-bearing capacity of profile: 6T Maximum plate thickness: 375kg/㎡

Machine tool external dimensions

About 33900mm* 5030mm*4100mm(length*width*height)

The gross weight of equipment

About 10500kg (Excluding air compressor, laser andother peripherals)

A-axis swing angle

±90°

C-axis swing angle

±90°

Max. linkage speed of X and Y axis

50m/min

Max. acceleration of the equipment

0.5g

Special typesetting software

Germany Befewest / WISCUT

The system recognizes file formats

DXF、DWG、IGS、IGES、STEP、STP、NC1

The size of the center distance between the hole

and the wing plate

≥60mm (hole diameter ≤20mm)

Workpiece cutting length accuracy error

<1mm

φ 20mm hole position deviation

≤1mm

Overall power/current

12KW:92.50kW/175.68A 20KW:134.10kW/203.75A

Rated power supply voltage

380V

Frequency

50Hz

Total power supply protection level

IP54

Equipment Configuration

Gantry-type Steel Profile Laser Composite Processing Center | Dowell Laser selects core components from leading global brands, equipped with a high-power fiber laser, professional cutting head, and high-end CNC system, matched with high-precision guide rails and stable transmission components. Modular configuration supports flexible customization, integrating cutting, drilling, and grooving multiple processing steps. The high-rigidity frame ensures stable equipment operation, laying a solid foundation for efficient production in steel structure and engineering machinery processing.

Item.

Brand

Configuración

Laser source

Max./Raycus

The spot quality is good,the signal transmission is stableand the anti-interference ability is strong.

Automatic focusing laser head

WSD - WF series

Integrated structure, double water cooling design, good heat dissipation, stable light output.

Numerical control system

WISCUT

EtherCAT bus control, the third generation of follower system, closed-loop control is more accurate, faster response, higher processing efficiency.

Servo motor drivers

HCFA/Flexem FBOX

The bus moter and driver cooperate withe the bus system to realize the bus control.

High precision linear guide rail (Heavy rail is used for the bed axis)

Taiwan TBI/HIWIN

High standard H grade

High precision rack (The bed shaft is straight)

YYC

High standard 6 level

Water cooling chiller

S&A/Hanli

Double temperature control, efficient and environmental protection.

Longitudinal components

Dowell Laser

It is made of high quality steel plate welding, and aging treatment is adopted after welding to eliminate internal stress, so it is not easy to deform in long-term use.

Z-axis assembly

Dowell Laser

High precision screw transmission mode is adopted.

Steel bed base (Optional)

Dowell Laser

Made of high quality profile welding, durable and stable.

Single station profile support device, Single station plate processing table (The above two are optional)

Dowell Laser

Used to support profiles, Used to support panels.

WISDOM Intelligent Digital Cutting Control System

Adopting the WISDOM Intelligent Digital Cutting Control System is a core choice for Dowell Laser to enhance equipment performance, optimize production efficiency, and solve real pain points for global metal fabricators. Its unique advantages perfectly match Dowell’s pursuit of precision, intelligence, and efficiency, specifically reflected in 6 key aspects:

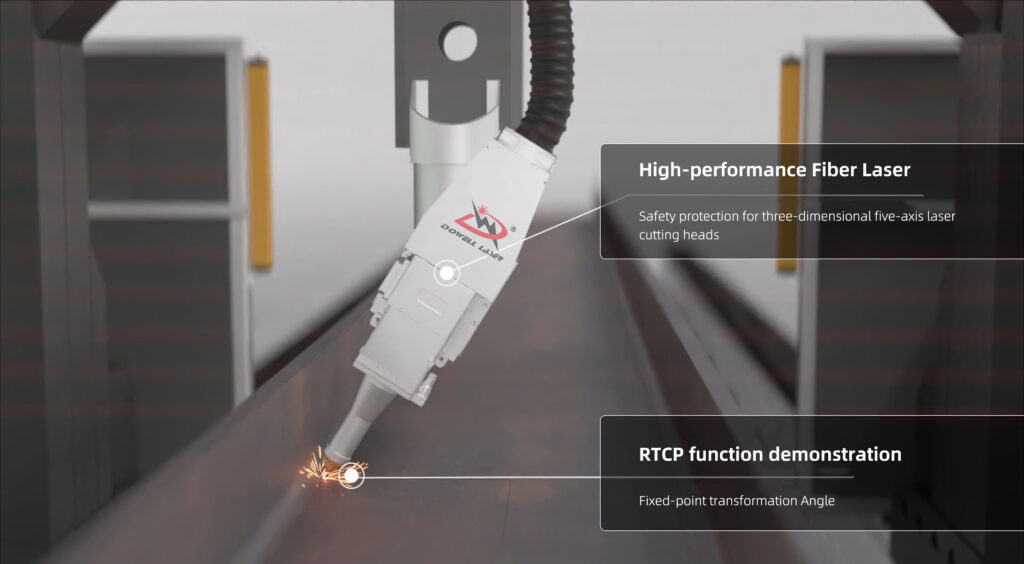

Transmission Structure

Key components are processed and produced by DMG five-axis machining center, and the laser head is driven by precision screw transmission inside to ensure positioning accuracy;

Laser Lens System

The collimation lens group and focusing lens group are both composed of composite lenses, and the automatic focus adjustment range can be from +10 to-12mm, which can obtain the optimal optical quality and cutting effect;

Driver System

External drive motor, built-indrive unit, the drive motor is completely separated from the lens barrel cavity, can effectively prevent mechanical wear and tear debris pollution of the lens;

Water Cooling System

Using the full week water cooling form, the optical fiber interface, collimation lens group and focusing lens group can be fully cooled, and the service life of each lens group is longer;

Levels of Protection

High level of sealing standard, can not only prevent dust from entering, but also prevent splashing water intrusion, in the laser industry is a higher standard;

Laser Head Nozzle

The unique tip structure design makes it easier to process various types of pipe materials, open pipe materials, etc.

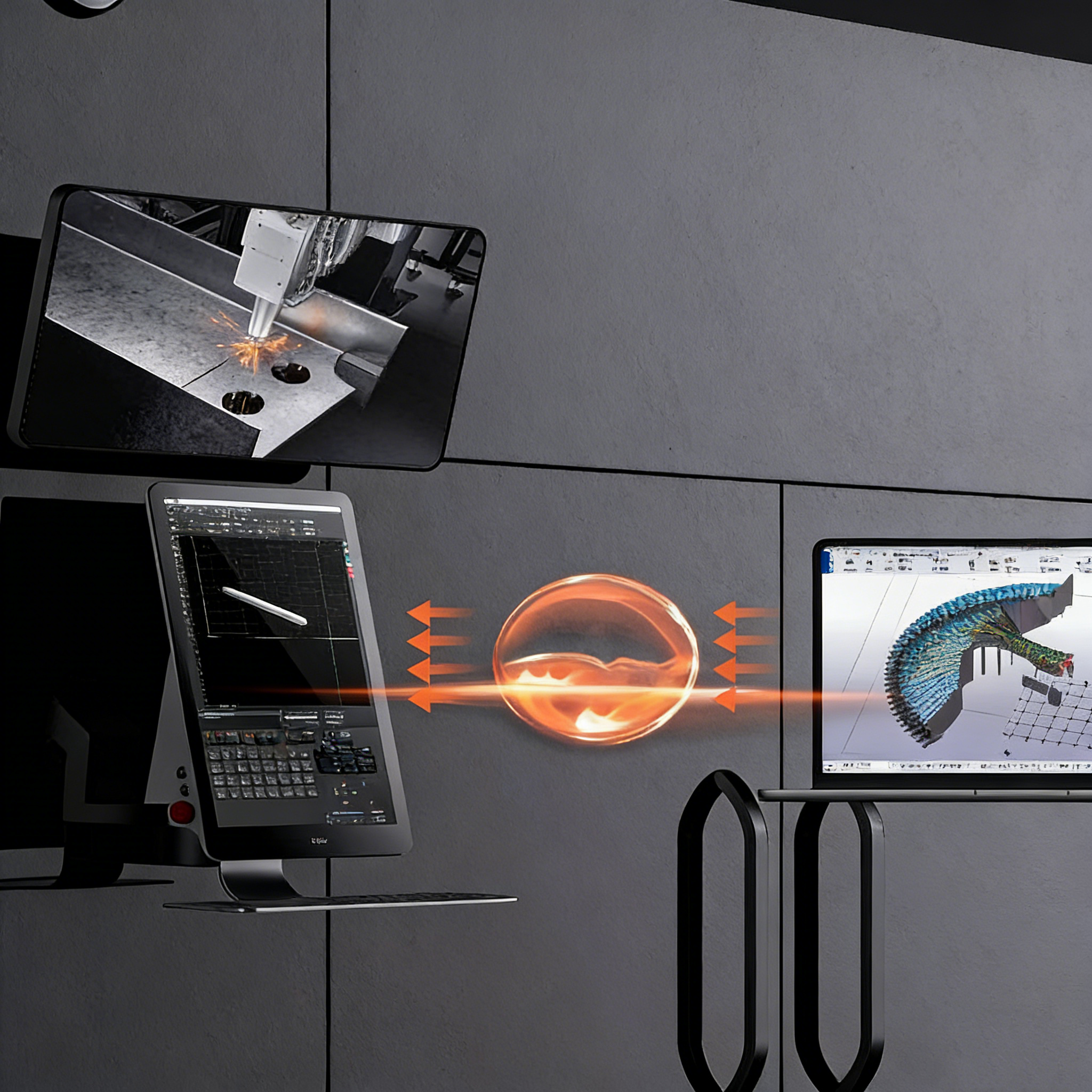

Germany WISCUT Laser Operating System

WisCut is a series of laser cutting operating software independently developed by Wuhan Wisden Intelligent Control Technology Co., Ltd. It is widely used in the steel structure processing field, and performs particularly well in high-precision applications such as H-beam cutting, bevel cutting, and 3D five-axis simultaneous control. Based on the German Beckhoff EtherCAT bus CNC system, the software integrates functional modules such as servo debugging, posture transformation, and visual calibration, significantly reducing equipment debugging difficulty and improving cutting accuracy and efficiency.

Wiscut Operating System brings intelligent human-computer interaction experience tousers, employing third-generation motion algorithms for more precise control, fasterresponse,and higher processing efficiency. The integration of CAD and CAM allows direct recognition of drawings, with the drawing area displaying the edges, expansion surfaces, and center lines of pipes. The software supports various file formats including DXF, DWG, IGS, IGES, STEP, STP, and G-code, enabling pre-processing of imported graphics such as removing duplicate shapes and converting text to graphics. The control system is equipped with numerous practical functions like progressive punching, segmented punching, three-level punching, automatic leveling and centering, micro-linking processes, and edge control, making operations simpler.

- Intuitive, simple, humanized and visual operation interface

- Real-time 3D display of actual machining parts and cutting trajectory, cutting status at a glance

- The integrated bus cutting head is cut and the state of the cutting head is monitoredinrealtime to realize closed-loop control and intelligent cutting processing

- Classified by components and functions, the operation and setting are displaye dcentrally.The operation is simple, the debugging is fast, and it is easy to handle

- LPS steel measurement compensation function: Laser laser line scan-Point spatial pointcloud-CNC numerical control compensation

- Special process database for steel: R Angle, groove, wing plate, web plate, air cutting, weldinghole, lock mouth and other cutting processes

- Supports a variety of mechanical structures such as gantry-type and automatic feeding

- Support the cutting and processing of a variety of special steel: such as, variable diameter beam, crane beam, etc

- Support the section line cutting of steel and round tube splicing

Adopt the Top-tier Chinese Brand Max/Raycus Laser Source

The laser uses high brightness pumping module and advanced optical fiber fusion technology to improve the conversion rate of electro-optics and beam quality, and reduce the use cost. The cutting section quality is higher, and the cutting speed is increased by more than 13%.

High Electro-optical Conversion Rate

High efficiency pump source and high quality optical fiber are selected, advanced fiber fusion technology and reasonable layout of optical fiber and devices are used, so that the electro-optical conversion efficiency of the laser can reach up to 40%;

Stable Power Output

The real-time monitoring of multiple key points, such as real-timemonitoring of output power, return light detection, etc., to ensure the safety of the laser;

Lower Power Attenuation Rate

The multiple high-power pump combinations are selected to make the power redundancy higher than the industry level;

Customized Fiber Length and Core Diameter

The fiber length and core diameter canbe customized according to the actual working conditions, which is convenient for userstouse;

Procesamiento de acero en forma de H, solución integral

Puede realizar fácilmente una serie de funciones en acero en forma de H, como cortar, bloquear, biselar, marcar, etc.

Cortar

biselado

Cortar agujeros

Accesorios Opcionales

Dispositivo de alimentación automática

Los tubos cuadrados, los tubos redondos, los tubos rectangulares, las vigas en I, los canales de acero, etc. se cargan en la posición designada, y se pueden cargar 5 tubos al mismo tiempo, y la altura se puede ajustar automáticamente para que coincida con los tubos, asegurando de manera efectiva la confiabilidad del soporte.

Dispositivo de carga de montaje lateral

Adecuado para cortar tuberías de metales pesados, puede realizar operaciones totalmente automatizadas como alimentación, corte y descarga automáticos, mejorando así en gran medida la eficiencia de producción; mejorar la tasa de utilización de las tuberías, maximizar el uso de materiales de tuberías de acero y reducir el desperdicio;

ejemplos de corte por láser

Adecuado para materiales metálicos, especialmente para cortar acero en forma de H (también conocido como viga en I o acero en H), como canal de acero, ángulo de acero, acero al carbono, para lograr corte, ranurado y apertura multifuncional, gráficos y texto. , grabado y corte en bisel Apertura de arco y otras funciones.

Aplicación de usos de la máquina de corte por láser.

The Cost Analysis of Equipment Usage

Unlike traditional processing equipment with high energy consumption, high labor input and high maintenance costs, Dowell Laser Cantilever-type Section Steel Laser Processing Center has obvious advantages in comprehensive use cost, and every detail is designed to help enterprises save costs while improving production efficiency.

1. The Equipment Electricity Cost

| Overall Power | Power Consumption of the Machine | Electricity Cost |

|---|---|---|

| 90.65KW | 90.65*0.7=63.4KW/H | 63.4*1=63.4 Yuan/H |

The data involved in the table is based on the DW26035 Cantilever-type Steel Section Laser Processing Center-12000W, in which the power capacity of the whole machine specifically includes the laser, water cooling machine and equipment host, including the air compressor;

The electricity price involved in the table is based on Jinan City, Shandong Province, and the price varies slightly in different regions;

2. The Cost of Vulnerable Parts

| Durable Parts Project | Power Up to 12000W |

|---|---|

| Cost of Protective Lenses | 3.5 Yuan/Hour |

| Nozzle Cost | 0.5 Yuan/Hour |

3. The Auxiliary Gas Cost

| Auxiliary Gas Type | 3mm Stainless Steel Cutting Speed and Gas Cost | 6mm Carbon Steel Cutting Speed and Gas Cost |

|---|---|---|

| Oxygen | / | 3m/min (10 Yuan/Hour) |

| Nirtrogen | 8m/min (Liquid Nitrogen 19.4 Yuan/Hour) | / |

| Air | 8m/min (10.5 Yuan/Hour) | 4m/min (10.5 Yuan/Hour) |

- The data involved in the table is based on DW26035-12000W as an example. When using air cutting, the use cost is mainly the electricity bill when the air compressor works;

- For carbon steel, under normal circumstances, oxygen processing is required to achieve a fine and smooth cut surface; we can also use air to cut thinner sections of carbon steel, which will increase the cutting speed; for stainless steel, under normal circumstances, nitrogen processing is needed to maintain the original metal color of the cut surface; we can also use air to cut thinner sections of stainless steel, but the cut surface will turn gray, and the cutting cost is relatively lower;

- The capacity of a regular bottled nitrogen is 40L, approximately 30 yuan per bottle, requiring about 4 bottles per hour (the output pressure is adjusted to 20 bar, with a purity of 99.9%), making the hourly nitrogen consumption about 120 yuan per hour; the capacity of a canister of liquid nitrogen is 500L, approximately 700 yuan per can, each can of liquid nitrogen can last for about 36 hours (the output pressure is adjusted to 20 bar, with apurity of 99.99%), making the hourly nitrogen consumption about 19.4 yuan per hour;

- Liquid nitrogen is cheap to use and does not require frequent air changes, so customers are advised to use liquid nitrogen to process materials such as stainless steel.

4. The Total Equipment Cost

| Cost Item / Material and Thickness | 3mm Stainless Steel | 6mm Carbon Steel |

|---|---|---|

| Equipment Electricity Cost | 63.4 Yuan/Hour | 63.4 Yuan/Hour |

| Cost of Vulnerable Parts | 4 Yuan/Hour | 4 Yuan/Hour |

| Auxiliary Gas Costs | 10.5 Yuan/Hour (Air) | 10 Yuan/Hour (Oxygen)) |

| Total Operating Cost of the Equipment | 77.9 Yuan/Hour | 77.4 Yuan/Hour |

get in touch

Don’t hesitate! Contact us via email, phone or online message, and we will reply within 24 hours. Let us help your enterprise break through traditional bottlenecks, enhance competitiveness and achieve sustainable profit growth. Choose us, choose a reliable partner for your production upgrading.

Visit our office

Dakota Dr, San Jose, CA 95111, USA

Message us

+088 145 5846 695