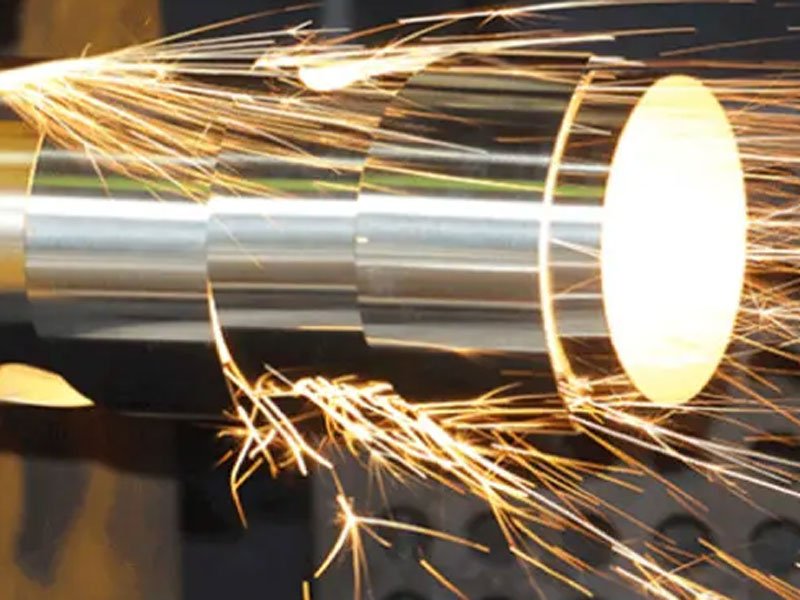

Metal round pipe laser cutting machine cutting round holes is not as simple as everyone thinks. Irregular round holes and insufficient verticality are also occasional things. Dowell round square pipes fiber laser cutting machine factories give everyone an analysis of the reasons and precautions.

Many customers have encountered the problem that the round hole cutting is not very good когда using the metal pipe cutting machine. This article will tell you some solutions, I hope it will be helpful to you.

Что to do if the round hole is too small?

1.The quality of cutting round holes has certain requirements for the servo motor

A better solution for cutting round holes with a tube laser cutting machine is a round hole ratio of 1:1, which means that the ratio of the hole diameter to the plate thickness is 1:1. The larger the hole diameter, the easier it is to cut high-quality round holes.

2.The servo motor parameters are not adjusted properly

The circular hole sometimes appears elliptical or irregular. This is related to the mismatch of X\Y axis movement, and the direct cause of the mismatch of X\Y axis movement is. Otherwise, когда the energy of the fiber laser cutting machine is insufficient, the small holes will be easily cut and the broken points will remain and the round holes will not be round.

3.The perfect cooperation between the craftsman and the machine

During the blowing process, когда the air pressure is too low, slag scraping and carbonization will occur at the edges, and the holes will burst easily if the pressure is too high. Therefore, it is required to choose the right air pressure based on experience to make the cut round hole more full.

4.The strength of the laser cutting machine manufacturer is related

The precision error of the руководство rail and the lead screw will directly lead to the accuracy of the round hole not reaching the expected。

Metal round pipe laser cutting machine can not cut through

1. Laser power is too low

Only with sufficient power can the tube wall be cut through. If the laser power is too low, the cutting depth is insufficient, resulting in incomplete cutting.

Когда using a laser tube cutting machine, it is necessary to ensure that the laser power is sufficient and select different laser powers according to different tubes.

2.Optical path error

Whether the optical path of the laser tube cutting machine is correct will also affect the cutting effect. If the optical path is incorrect, the laser may not be accurately focused on the tube wall, resulting in incomplete cutting.

It is necessary to check whether the optical path adjustment is correct to ensure that the laser can accurately focus on the tube wall.

Laser tube cutting machine cutting round tube problem

Unstable or inaccurate pipe cutting length:

Check whether the front baffle is loose or not positioned correctly. If so, fix the front baffle to prevent it from loosening.

Check whether the conductive device is loose or in poor contact. If so, tighten the conductive device and ensure good contact.

Cutting process does not cut continuously:

- Ensure that the rotation angle of the rotary chuck is not less than 360 degrees. If it is insufficient, the rotation angle parameter should be adjusted to 365-375 degrees.

- Check whether the air pressure is sufficient. If the air pressure is insufficient, the air pressure should be adjusted to an appropriate level.

- Check whether the laser lens is dirty or the focus is not adjusted properly. If so, the lens should be replaced and the focus should be readjusted.

- Check whether the nozzle is blocked or damaged. If so, the nozzle should be replaced.

Too many burrs inside and outside the pipe:

- Check whether the copper nozzle is loose. If it is loose, the copper nozzle should be fixed.

- Check whether there is iron slag adhering to the copper nozzle. If so, the iron slag should be removed.

- Recalibrate the height adjuster and ensure that the pipe is clamped during calibration.

- Check whether the laser head protective lens is damaged or has black spots. If so, it should be replaced in time, and the dust on the laser head should be cleaned before replacement.

- Ensure that the focus is adjusted correctly. If necessary, readjust the focus.

- Check whether the laser light is aligned with the center of the copper nozzle. If not, adjust the laser light position.

Therefore, it is recommended that in the process of purchasing laser pipe cutting machines, try to choose high-quality and big-brand products. Pay attention to whether the precision, speed and other parameters of the circular hole of the laser pipe cutting machine meet the standard requirements to identify whether the quality of the laser pipe cutting machine purchased is satisfactory.