Customized Metal irregular tube laser cutting machine for Sale

- Marca: MÁQUINA LÁSER DOWELL

- Tipo de láser: láser de fibra

- Work Length 6m/9m/12m/24m

- The auxiliary system includes cooling and dust removal systems. The cooling system lowers the temperature of the laser source and optical path system,

- Cooling Mode: WATER COOLING

- Applicable Material Metal

Introducción

Irregular/Special Shapes Tube laser cutting machine high degree of flexibility allows them to cut tubes with complex geometries and contours. Suitable for a wide range of industries requiring unique or customized tube shapes.

Parámetros técnicos

- Marca: Dowell Laser

- Power: 1000w-12kw

- Laser Head Brand: Boci/Ospri/Raytools/Customized

- Laser Source Brand:MAX / RECI/IPG/RAYCUS

- Cutting Materials: Stainless Steel/Alloy Steel/Aluminum/Copper/Iron

- Contral System: Cypcut(Fscut)

- X/Y-Axis Positioning Accuracy :0.05mm/M

- Applicable Industries:Metal Cutting Industry

- Keyword :Metal Pipe Laser Cutting Machine

- Cutting speed:Max 0.8s/cut(Depending on material thickness)

- Machine repeat positioning accuracy:±0.05mm/1000mm

- Place of Origin:Shandong, China

best irregular tube laser cutting machine for sale

Video

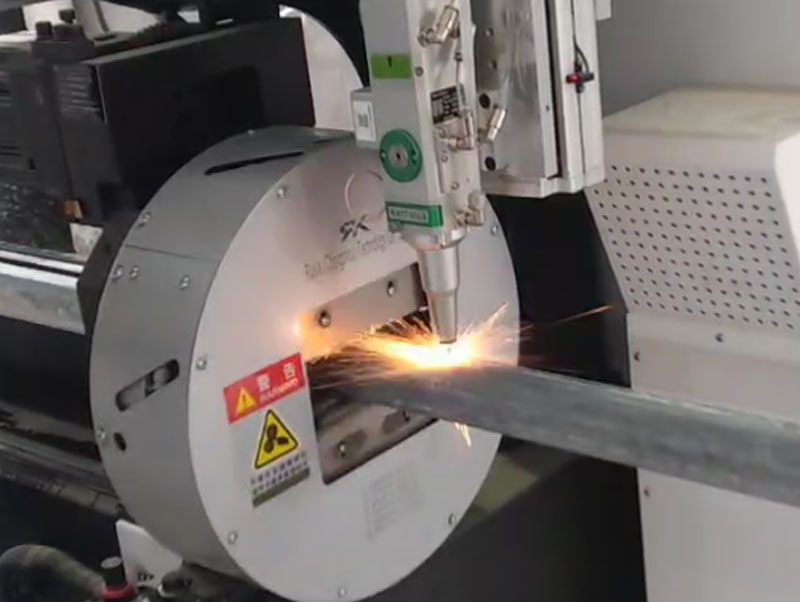

laser cutting channel steel

fiber laser cutting rectangular tube video

Características

- Capable of cutting round, square, rectangular, and irregular-shaped tubes

- Handles a wide range of tube diameters, from 8 mm up to 356 mm

- Can cut tube lengths up to 9200 mm

- Utilizes a multi-axis cutting head for high-precision bevel cutting

- Fiber laser technology provides fast cutting speeds up to 160 m/min

- Laser power options range from 1 kW to 20 kW for cutting various thicknesses

customized irregular tube fiber laser cutting machine

DOWELL is a leading manufacturer of irregular tube laser cutting machines with over 15 years of experience in the laser equipment industry. Our round tube laser cutting machines are exported to various countries, including Egypt, Russia, and Saudi Arabia, and are designed to meet the customized needs of our clients.

We offer customization options for tube diameters ranging from 200 mm to 350 mm, ensuring that we can accommodate special models as required. Our commitment to providing the most competitive prices in the market makes us a preferred choice for customers seeking quality and affordability.

If you have specific customization needs or require a quote for our circular tube laser cutting machines, please feel free to contact us for the latest pricing and information.

Preguntas más frecuentes

Can I customize the cutting patterns on irregular tubes

Yes, you can customize the cutting patterns on irregular tubes using advanced laser cutting technology. Many laser cutting machines are capable of handling complex shapes and designs, allowing for a high degree of customization.

How does the price of DOWELL's laser cutting machines compare to other manufacturers

Tube Diameter Range

Tubes with diameters ranging from 200 mm to 350 mm can be accommodated

This wide range allows for cutting of both standard and custom tube sizes

Irregular Tube Shapes

In addition to round tubes, the machines can cut square, rectangular, and other irregular-shaped tubes

This flexibility enables the creation of complex designs and profiles

Precisión de corte

Typical cutting tolerances range from 0.1 mm to 0.3 mm

Kerf sizes (cut width) are between 0.2 mm to 0.5 mm, minimizing material waste

Versatilidad de materiales

The tube laser cutting machines can handle a variety of metal materials, including steel, stainless steel, aluminum, and copper

This material versatility expands the range of applications for the machines

Automation Options

Semi-automatic and fully automatic tube loading and unloading solutions are available

Automated systems can improve efficiency, reduce labor costs, and enable continuous operation

By offering these customization options, DOWELL ensures that their round tube laser cutting machines can be tailored to meet the specific requirements of each customer’s application and production needs.

What software tools are available for designing custom cutting patterns on irregular tubes

CAD/CAM Systems

Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems are powerful software solutions that allow you to create digital patterns and cutting designs for irregular tubes. These systems offer precision, efficiency, and the ability to store and modify patterns easily.

Some popular CAD/CAM software options include:

AutoCAD – A widely used CAD software that supports 2D and 3D design

SolidWorks – A 3D CAD program that enables the design of complex shapes and patterns

Autodesk Inventor – A 3D CAD software with advanced modeling capabilities

Pattern Making Software

Specialized pattern making software like PatternSmith from Autometrix provides industry-leading tools for pattern drafting, editing, nesting, and machine control. These programs simplify the entire process from creating patterns to precision cutting.

Key features include:

Intuitive pattern drafting and editing

Powerful nesting capabilities

Seamless integration with cutting machines

Customizable plugins and tools

Schematic Capture Software

While not directly related to tube cutting, schematic capture software like Eagle and gEDA can be used to design electronic schematics and PCBs, including custom tube circuit designs. These programs provide libraries of tube components and allow you to create detailed diagrams.

What consumables does the irregular tube laser cutting machine have?

The main consumables include auxiliary gas, cutting lens, focusing lens, nozzle, ceramic body, etc.

What should I do if the tube is deformed or the cut surface is tilted during the cutting process?

You can strengthen the operator’s skill training, master the control system, and improve the cutting quality.

What industries are irregular tube laser cutting machines suitable for?

Widely used in medical equipment, fitness equipment, fire protection/water supply and drainage/gas pipelines and other industries.

Prevention of common faults of Special Shapes Tube laser cutting machine

Regular cleaning, routine inspection, software update, cooling system maintenance, and take corresponding solutions according to specific faults