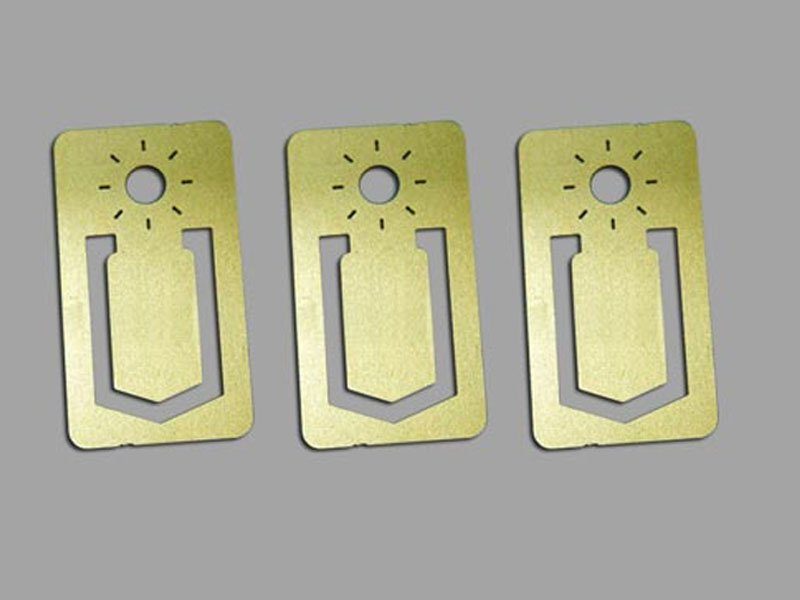

Copper is a versatile and widely used material in various industries, from electronics to construction. Cutting copper sheets with a laser cutter can be an efficient and precise method, but it requires specific techniques and considerations due to copper’s unique properties. In this guía, we will explore the steps and tips on how to cut copper sheets using a laser cutter.

What is Copper Sheet Laser Cutting

Copper is highly reflective and conductive, which can pose challenges for laser cutting. The reflection can cause damage to the laser cutter, and its high thermal conductivity can dissipate the laser energy quickly, making it difficult to achieve clean cuts. However, with the right approach and equipment, cutting copper sheets with a laser cutter is achievable.

Equipment and Materials Needed

- Laser Cutter: A fiber laser cutter is typically more effective for cutting copper than a CO2 laser cutter due to its wavelength, which copper absorbs better.

- Copper Sheet: Ensure you have the correct thickness of copper sheet for your project. Thinner sheets are easier to cut.

- Protective Gear: Safety goggles and gloves are essential to protect yourself from laser reflections and hot metal.

- Cooling System: Copper’s high thermal conductivity requires effective cooling to prevent warping or damage during cutting.

- Assist Gas: Using nitrogen or oxygen as an assist gas can help improve cutting quality and speed.

Step-by-Step Guide to Laser Cut Copper Sheet

1. Preparation

- Clean the Copper Sheet: Remove any dirt, oil, or oxidation from the copper sheet to ensure a clean cut.

- Secure the Sheet: Place the copper sheet on the laser cutter bed and secure it to prevent movement during cutting.

2. Setting Up the Laser Cutter

- Adjust the Focus: Ensure the laser is correctly focused on the surface of the copper sheet.

- Select the Appropriate Power and Speed Settings: This varies depending on the thickness of the copper sheet. Start with a lower power setting and adjust as needed.

- Use Assist Gas: Connect the nitrogen or oxygen assist gas to the laser cutter to enhance the cutting process.

3. Cutting Process

- Test Cut: Perform a test cut on a small piece of the copper sheet to fine-tune the settings.

- Monitor the Cut: During the cutting process, monitor the cut to ensure it is clean and precise. Adjust settings if necessary.

- Cooling: Ensure the cooling system is functioning correctly to prevent overheating and warping of the copper sheet.

4. Post-Cutting

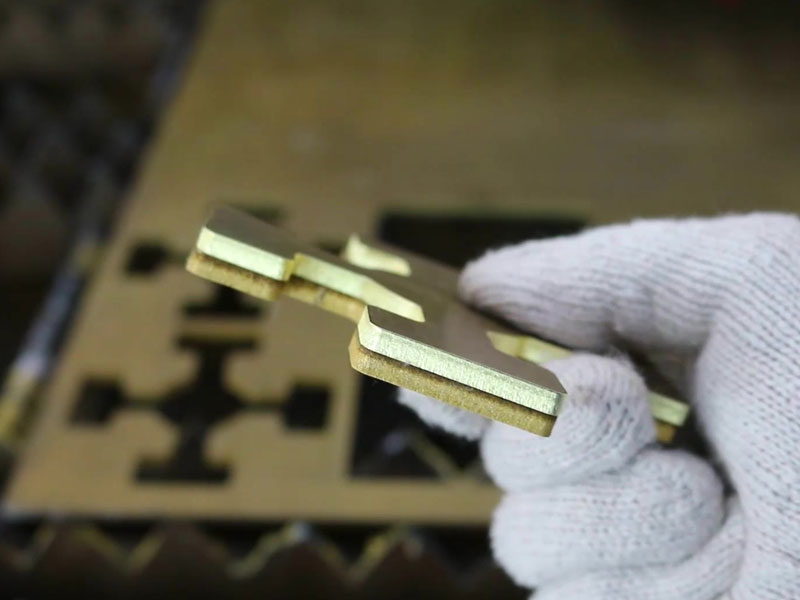

- Inspect the Cut Edges: Check the cut edges for any burrs or roughness. Use a deburring tool if necessary.

- Clean the Cut Piece: Remove any residue or assist gas markings from the cut piece.

Tips for Better Results

- Use a High-Power Laser: A higher power laser can cut through thicker copper sheets more effectively.

- Optimize Assist Gas Pressure: Adjust the assist gas pressure to achieve the best cutting quality.

- Maintain the Laser Cutter: Regularly clean and maintain your laser cutter to ensure optimal performance.

Safety Considerations

- Wear Protective Gear: Always wear safety goggles and gloves to protect yourself from laser reflections and hot metal.

- Ventilation: Ensure proper ventilation in the cutting area to remove any fumes generated during the cutting process.

- Follow Fabricante Guidelines: Adhere to the laser cutter fabricante‘s guidelines and safety protocols.

Will Laser Cutting Copper Shorten the Life of the Laser Source?

Laser cutting copper can indeed have an impact on the lifespan of the laser source, particularly if the proper precautions and equipment are not used. Here are some factors to consider:

Reflectivity of Copper

- Alta reflectividad: Copper is highly reflective, especially to the wavelengths typically used by CO2 lasers. This reflection can cause the laser beam to bounce back into the laser source, potentially damaging it over time.

- Using Fiber Lasers: Fiber lasers, which operate at a wavelength that copper absorbs more efficiently, can mitigate this issue. They are generally more suitable for cutting copper and can reduce the risk of reflective damage.

Thermal Conductivity

- Disipación de calor: Copper’s high thermal conductivity means it dissipates heat rapidly. This can cause inconsistent cuts and put additional stress on the laser source as it works harder to maintain the necessary cutting power.

- Effective Cooling: Ensuring effective cooling during the cutting process can help manage the heat dissipation and protect the laser source from overheating.

Assist Gas

- Using Assist Gas: Using assist gases like nitrogen or oxygen can help improve the cutting process and protect the laser source. These gases can help remove molten material and reduce the thermal load on the laser.

Laser Source Wear and Tear

- Power Settings: Running the laser at higher power settings to cut through copper can accelerate the wear and tear on the laser source. It’s essential to find the right balance between power, speed, and assist gas to optimize the cutting process without overloading the laser.

- Mantenimiento regular: Regular maintenance and calibration of the laser cutter can help mitigate some of the wear and tear associated with cutting reflective materials like copper. Ensuring that optics are clean and properly aligned can also extend the laser source’s life.

Protective Measures

- Anti-Reflective Coatings: Some laser cutters come with anti-reflective coatings or features designed to handle reflective materials like copper. Using a laser cutter with these protective measures can help prevent damage to the laser source.

- Beam Delivery System: Ensure that the beam delivery system is designed to handle reflections. Some advanced systems have features to absorb or deflect back-reflected laser energy away from the laser source.

Conclusión

Copper sheet laser cutting machine can be challenging due to copper’s reflective and conductive properties. However, with the right equipment, settings, and techniques, you can achieve precise and clean cuts. Always prioritize safety and take the time to fine-tune your laser cutter settings for the best results. Whether you are working on a small project or large-scale production, laser cutting can provide the precision and efficiency needed for working with copper sheets.

By following this guía, you’ll be well on your way to mastering the art of cutting copper sheets with a laser cutter. Happy cutting!