In modern manufacturing, laser cutting technology has become an indispensable part. With the continuous advancement of technology, the types of laser cutting machines are becoming more and more abundant. CNC tube laser cutting machine and manual laser cutting machine are two common types.

So, what are the differences between CNC Tube Laser Cutting Vs Manual Laser Cutting? Which one is more suitable for your production needs? This article will give you an in-depth analysis.

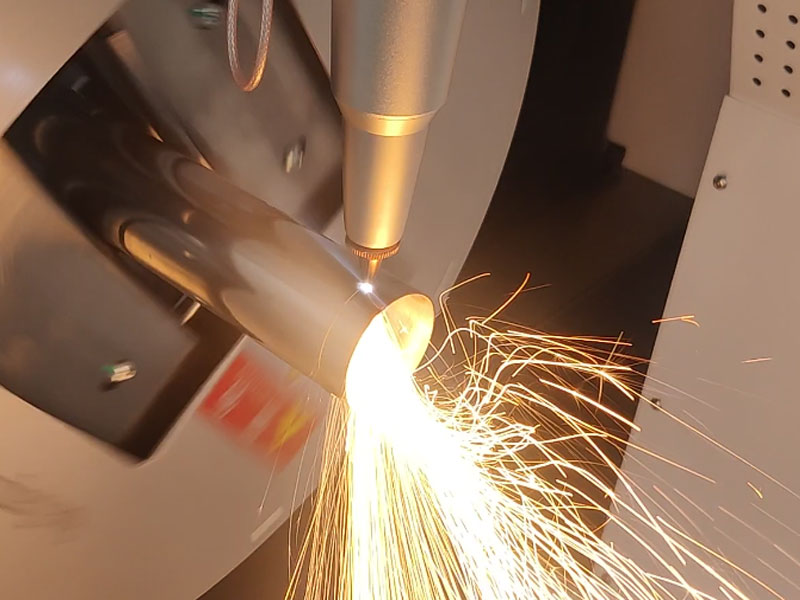

What Is a Cnc Tube Laser Cutting Machine?

A CNC tube laser cutting machine is a high-precision laser cutting device controlled by a computer. Through computer programming, the laser beam is focused on the surface of the workpiece, and the material is melted instantly using high energy to achieve cutting.

Features: high efficiency, high precision, high degree of automation, strong flexibility, programmable, etc.

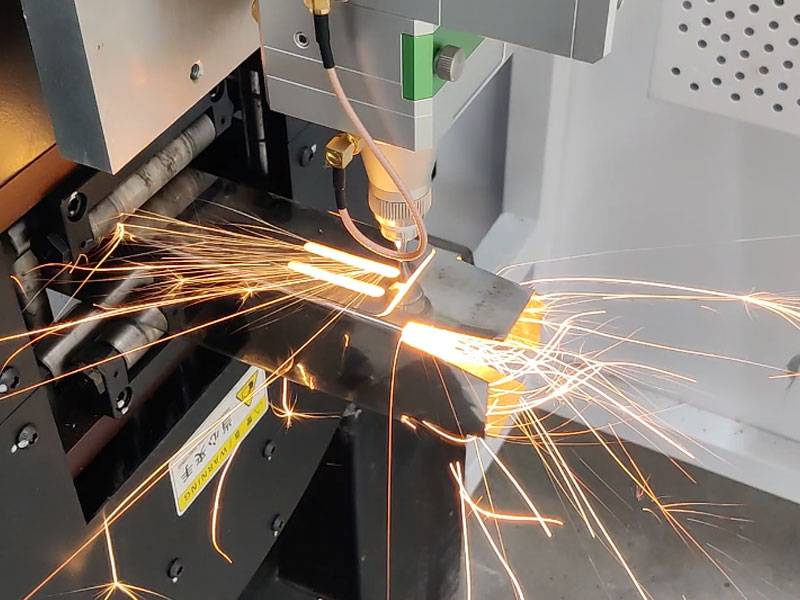

What Is a Manual Laser Cutting Machine?

A manual laser cutting machine is a laser cutting device that requires manual operation. The operator manually adjusts the position and power of the laser beam to achieve material cutting.

Features: low efficiency, poor precision, limited flexibility, and high technical requirements for operators.

CNC Tube Laser Cutting Vs Manual Laser Cutting Properties

| Característica | CNC Tube Laser Cutting Machine | Manual Laser Cutting Machine |

|---|---|---|

| Velocidad cortante | Extremely fast, reaching hundreds of meters per minute | Relatively slow, low efficiency |

| Precisión de corte | Micron-level precision, high repeatability | Millimeter-level precision, low repeatability |

| Compatibilidad de materiales | Wide range, capable of cutting various metals and non-metals | Limited, primarily for cutting thinner materials |

| Cutting Shape | Complex shapes, arbitrary curves | Simple shapes, straight lines or arcs |

| Automation Level | Highly automated, capable of unmanned production | Low automation, relying on manual operation |

Cnc Tube Laser Cutting Vs Manual Laser Cutting Cost

- Inversión inicial: The initial investment of CNC tube laser cutting machine is high, but in the long run, its high degree of automation can significantly reduce labor costs.

- Operation Cost: CNC tube laser cutting machine has low energy consumption and relatively low maintenance cost.

- Product Cost: CNC tube laser cutting machine produces high-quality products with low defective rate, which can reduce material waste and thus reduce product cost.

Application Field

- Metal Processing: Stainless steel tube, carbon steel tube, aluminum tube, etc.

- Automobile Manufacturing: Automotive parts, body parts, etc.

- Industria Electrónica: Precision electronic components, circuit boards, etc.

- Fabricación de muebles : Metal furniture frames, decorative parts, etc.

- Industria de construccion: Metal structural parts, decorative panels, etc.

How to Choose a Suitable CNC Tube Laser Cutting Machine

Material Type

Determine the type of material you will be cutting (metal, non-metal, etc.), which will affect the choice of laser. Fiber lasers are generally suitable for metals, while CO2 lasers are more suitable for non-metallic materials.

Tube Size

The size of the machine’s table and clamping device determines the maximum tube length and diameter that can be processed. Make sure the selected machine can handle the tube size you need.

Potencia del láser

Laser power directly affects cutting speed and penetration ability. Higher-power lasers can handle thicker materials and are generally selected between 1000W and 6000W, depending on your needs.

Cutting Accuracy

Evaluate the cutting accuracy requirements of your project. High-precision needs may require features such as autofocus and fine beam control.

Degrees of Freedom (DOF)

The degrees of freedom (number of axes of motion) of a laser cutting machine determine its motion capabilities and versatility. The more axes, the more flexibility and cost of the machine.

Conclusión

CNC tube laser cutting machine has occupied an increasingly important position in modern manufacturing industry with its advantages of high efficiency, high precision and high degree of automation. In contrast, manual laser cutting machine has obvious shortcomings in efficiency, precision and flexibility. If you pursue high efficiency and high quality cutting effect, CNC tube laser cutting machine is undoubtedly your best choice.