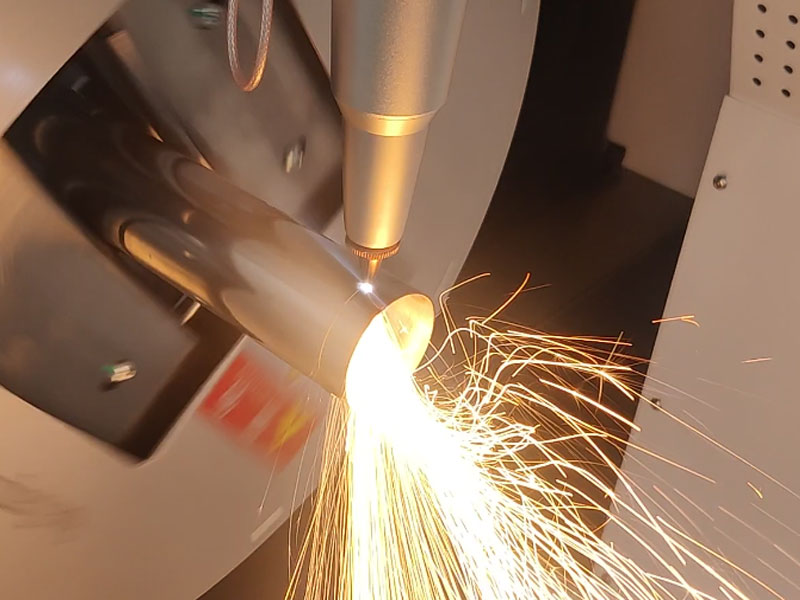

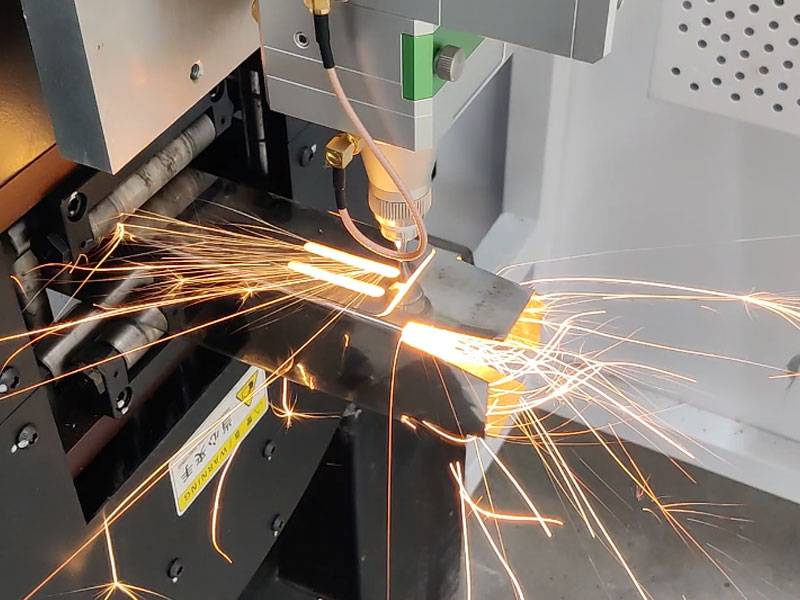

Tube laser cutting is a revolutionary manufacturing process that has transformed the metal fabrication industry. By harnessing the power of laser technology, manufacturers can achieve precise and efficient cuts on a wide variety of tubular materials.

Регулярная замена: guía, we will delve into the world of tube laser cutting services, exploring its benefits, applications, and the technology behind it.

What is Tube Laser Cutting

Tube laser cutting involves using a high-powered laser beam to cut through metal tubes with exceptional accuracy. The process offers numerous advantages over traditional cutting methods:

- Precisión: Laser cutting produces clean, burr-free cuts with minimal heat-affected zones.

- Velocidad: High-speed cutting reduces production time and increases efficiency.

- Flexibilidad: Laser cutting can handle complex shapes and intricate designs.

- Versatilidad: Suitable for a wide range of materials, including stainless steel, aluminum, and carbon steel.

Laser Tube Cutting Service Market

According to market research, the laser tube cutting service market is expected to grow from $2.42 billion in 2024 to $5.67 billion in 2032, with a CAGR of approximately 11.24%1. This growth is mainly driven by the increasing demand for high-precision and high-efficiency cutting solutions in multiple industries, especially in the automotive, aerospace, medical and construction fields.

Technological Advances

The continuous advancement of laser technology, especially the popularity of fiber laser technology, has significantly improved the speed and accuracy of laser cutting. This new technology can effectively process a variety of materials, including metals, plastics and composites, to meet the needs of complex designs.

Automation and Digitalization

The trend of manufacturing transformation towards automation and digitalization is driving the demand for laser tube cutting services. Companies hope to optimize production processes by reducing labor costs and improving production efficiency, and laser cutting services can provide automated solutions to reduce human errors.

Environmental Protection and Sustainability

With the increasing awareness of environmental protection, companies are paying more and more attention to reducing material waste and improving resource utilization. Laser tube cutting technology is favored for its high efficiency and low waste characteristics.

Benefits of Tube Laser Cutting Services

- Reduced Material Waste: Laser cutting minimizes material waste, resulting in cost savings.

- Improved Quality: The precise and consistent cuts produced by laser cutting enhance product quality.

- Faster Turnaround Times: High-speed cutting reduces production time, allowing for quicker delivery.

- Complex Shapes: Laser cutting can create intricate shapes and designs that would be difficult or impossible to produce using traditional methods.

- Automatización: Laser cutting systems can be automated, reducing the need for manual labor.

Challenges of Laser Tube Cutting Service

Inversión inicial

The cost of setting up a laser cutting facility for tubes is relatively high. The equipment, including the laser source, CNC system, and cutting table, can be expensive. Proper installation and training are required, adding to the initial investment. Over time, the benefits of increased productivity and quality can offset these costs.

Maintenance and Service

Laser cutting equipment requires regular maintenance to ensure optimal performance. This includes servicing the laser resonator, optics, and cooling system. Skilled technicians are needed to perform these maintenance tasks, and any failure can cause production downtime. It is critical to establish a reliable service and support network.

Material Thickness Limitations

While laser cutting of tubes can handle a wide range of tube diameters, there are limitations when it comes to material thickness. Extremely thick materials may require a more powerful laser or multiple passes, which can affect cutting speed and quality. Manufacturers need to consider the thickness requirements of their projects and ensure that the laser cutting equipment is appropriate for the material thickness.

Zona afectada por el calor

The intense heat generated during the laser cutting process creates a heat-affected zone (HAZ) in the material. This causes changes in the material’s microstructure and properties, such as hardness and strength. Minimizing the HAZ is critical, especially in applications where material integrity is critical. This can be achieved by properly choosing the laser parameters and assist gas.

Future development trend of tube laser cutting services

Intelligent manufacturing

With the development of Industry 4.0, intelligent manufacturing will become an important trend in the future. Integrated sensors, Internet of Things (IoT) and other emerging technologies will make laser tube cutting services more intelligent, improve production efficiency and product quality.

Green manufacturing

With increasingly stringent environmental regulations, green manufacturing will become an important direction for future development. Companies will pay more attention to reducing waste emissions and improving resource recycling, and laser tube cutting technology will be more widely used due to its low waste characteristics.

New material application

With the continuous emergence of new materials (such as composite materials), laser tube cutting services will play a greater role in these fields. Companies need to constantly update their equipment to adapt to the challenges and opportunities brought by new materials.

Conclusión

The laser tube cutting services market is developing rapidly, and the demand for high-precision and high-efficiency solutions in various industries has driven this trend. With technological progress, increased automation and enhanced environmental awareness, the future market prospects are broad. However, companies also need to face challenges such as equipment investment and technical training. In this context, continuous innovation and adaptation to changes will be the key to the success of enterprises